Process plant engineers consistently prioritize two critical goals when it comes to sight glass management: preventing unexpected downtime and minimizing safety risks from potential system failure. Sight glasses may seem like simple components; however, their failure can halt production for extended periods and create significant safety hazards.

While there are various options for sight glass materials, one type of sight glass, METAGLAS®, offers a unique advantage that is not well known—METAGLAS sight glass observation components are uniquely reusable. This feature not only extends service life but can also help reduce plant downtime while enhancing operational safety.

Experienced Industry Veteran Couples Fluid Engineering with Team Leadership

Experienced Industry Veteran Couples Fluid Engineering with Team Leadership

We’re excited to announce a significant addition to our leadership team at LJ Star. Joel Feldman has joined us as chief operating officer, bringing with him a wealth of experience in engineering leadership and product development that will help shape our future growth and innovation.

A Passion for Premium Solutions

Throughout his career, Joel has demonstrated an unwavering commitment to developing premium solutions that meet complex customer needs. His approach aligns perfectly with LJ Star’s dedication to providing high-quality process optimization equipment that our customers can rely on. “I’ve always been drawn to businesses that focus on the premium end of customer solutions,” Joel notes. “LJ Star’s reputation for quality and service provides an excellent foundation for future growth.”

Are you looking for better insight into your processes? Or to prevent waste? Improve safety? Enhance product quality? A sight glass observation port can check all these boxes and more. However, there are boxes equally as important to check off to select the right sight-glass window for your tanks and process vessels.

Color, clarity and consistency. These are just three characteristics that operators can monitor with a sight glass observation port when processing food or beverage products. A sight glass window can supply a visual means to ensure proper blending or mixing, accurate measurements and adherence to stringent quality standards.

Increase your ROI on Sight Glass Windows Using These Tips

Materials traceability is becoming an essential business practice to trace and certify sources for all parts and processes. It enables companies to track production, monitor issues, control recalls, or order replacement parts more easily. It helps highlight the importance of material selection at a project’s beginning or during the design phase.

The adage about a picture being worth a thousand words translates more pragmatically into worth measured in dollars in industries that requires or benefit from process observation and analysis. A ruined process or a wasted batch costs companies money and wastes time, while observation can help prevent such occurrences.

A sight glass observation port provides a view into the interior of the process vessel or tank. It supplies numerous benefits to monitor the vessel’s contents and processes, such as ensuring chemical reactions occur at the appropriate time, that liquid or fluid levels are maintained or that cleaning processes are conducted properly, as a few examples.

Presenting the pros and cons for biopharmaceutical processing

Single use technologies (SUTs) entered the biopharmaceutical industry in the 1990s, and processors were quick to take advantage of this alternative to traditional stainless-steel tanks /equipment for production lines. Single use production runs a process through equipment one-time using high-performance polymers for disposable components that have been sterilized using gamma irradiation. Over time, companies have sifted through the pros and cons of both types of technologies, SUTs and stainless steel, to determine the best options for business operations.

Process Observation Solutions: LJ Star Design Capabilities Enable Sight Glass Window Customization

The best process observation window might not be in a catalogue or sitting on a warehouse shelf. It might exist as an idealistic drawing on the back of a napkin. Or the opposite of ideal might be expressed in an email, as mounting frustration related to sight glass windows that repeatedly fail, bringing production to a halt and necessitating continual replacement orders.

The team at LJ Star can help guide the process of designing and fabricating custom orders for sight glass windows to make it easy for you to turn idealistic concepts into viable reality and end your frustrations. We can help analyze your process observation parameters and work collaboratively on a new design that best fits the needs of your operation. Getting started, it helps to understand some of the factors that demand a custom approach and which options can get the sight glass observation port from a sketch into operation.

LJ Star Expands Capacity Designed to Accelerate Supply Chain Deliveries

Twinsburg, Ohio – August 9, 2022 – LJ Star Inc., (www.ljstar.com), the leading provider of process observation equipment, announces a major facilities expansion to its headquarters in Twinsburg, Ohio. The recently completed construction project doubled its warehouse and manufacturing space and increased office space by 50 percent.

LJ Star expands due to steadily increasing demand for its products and services, which has led to LJ Star realizing, on average, more than a 13% annual growth rate (AGR) during the past several years. The company has added new personnel to help manage its business growth. The increased space, particularly the warehouse storage and handling capacity, will enable LJ Star to fulfill parts and product orders from stock, providing immediate delivery for many of its products.

“We made a significant investment to increase our square footage with a particular focus on warehouse capacity,” said Ted Mielnik, President of LJ Star Inc. “This allows us to maintain larger inventory levels for on-time delivery and order fulfillment. Global supply chain issues are causing increasing concern for companies of all types and sizes. Domestic availability of critical parts and shortened lead times should help our customers meet their business goals and objectives and retain a valuable competitive edge.”

The expansion is tied to the strong market conditions in the sectors targeted by LJ Star, including pharmaceuticals, food/beverage, chemical, and oil & gas, for demanding process applications that require the highly engineered solutions LJ Star offers. As those industries expanded their own capacities aggressively during the pandemic, LJ Star has seen a corresponding demand for its sight glasses, sight flow indicators and process lights. This enables LJ Star to keep pace supplying essential parts for new production lines and facilities its customers have built, particularly during the pandemic expansion era.

This is part of a company-wide investment policy to improve products and services at its Ohio location as well as at its sister company Tank Components Inc. in Missouri. In the past few years Tank Components has added capital improvements including plate rolls for the Cylinder Department, an HD Plasma Table for the Tank Head Department and a CNC Turning Center for the Machine Shop, to name a few.

About LJ Star

LJ Star Incorporated (www.ljstar.com) provides an extensive line of process observation equipment – sight glasses, process lighting, sanitary fittings, and level gage instrumentation. Product lines include METAGLAS® Safety Windows, Lumiglas® Explosion Proof Lights and Cameras, the MetaClamp® Sanitary Sight Window, Visual Flow Indicators, Sight Ports, Sanitary Clamps, Magnetic Level Gages and Gage Glass. METAGLAS® is the #1 selling fused sight glass, proven in thousands of installations around the world. Unlike some other sight glasses, it meets stringent DIN 7079 and DIN 7080 quality standards, and it is approved for USP Type I use.

ATEX and UL Certifications.

Manufacturers must meet a variety of standards to ensure the safety of their employees and their communities. In such industries as chemical and petrochemical, for example, vapors and mists escape during the production, processing, transportation and storage of flammable substances and during the production of mineral oil and natural gas. In such potentially explosive environments, it is critical to use certified equipment that can safely operate in these hazardous conditions.

A variety of certification standards regulate equipment used in explosive environments. Two of the most common sets of standards are ATEX and UL.

Process engineers typically question, when specifying equipment to be used in both Europe and the United States, what the ATEX and UL equivalencies are. In other words, if I specify something for ATEX Zone 1 or Zone 28, what is the corresponding UL Class and Division? The reverse applies as well for those specifying a UL level of performance. While this is a complex and technically precise question, we’ll address some general guidelines here.

A recent article in Food Processing highlighted the importance of a master sanitation schedules. Essentially this schedule serves as a “back-up” to your daily maintenance procedures but involves the periodic cleaning and care for equipment and infrastructure inaccessible to daily cleaning activities.

The article covers two essential parts of the master sanitation schedule – the creation of the schedule and validating the procedures outlined in the schedule.

Schedule Creation

The starting point of creating the schedule, according to the article, is identifying where in your process you have contamination risk. Where are parts that could become a risk, either from poor design, material composition, process requirements, or other factors? Once identified, these non-compliance risks should be analyzed, and a set of cleaning requirements determined and added to the master sanitation schedule.

Schedule Validation

The practical application of the schedule requires validation. The article lays out a method that involves disassembly to reach the parts and visual inspection prior to taking samples both before and after the outlined cleaning. In this way, possible contaminants can be identified, and the cleaning procedure’s effectiveness and frequency are ensured.

Sight Glasses – A Window Into Your Master Sanitation Schedule

It stands to reason that the more parts that are a contamination risk and not readily accessible, the longer your master sanitation schedule, and the more production time lost to accessing and cleaning those parts. However, using accessible and hygienically designed equipment can reduce the number of items that could pose a contamination risk and reduce the time and effort needed to address them in the master sanitation schedule.

LJ Star has several products that fit those criteria.

Our sanitary sight glasses let you see more parts of your process, eliminating unknown corners that could become a concern while offering improved hygienic operation. Properly installed sanitary fittings make disassembly easier to perform and are less likely to add to contamination risks. In addition, LJ Star offers flow indicators, sight windows, bubble traps, and other sanitary products designed to meet various hygienic standards, along with the documentation and traceability to ensure they are, when properly maintained, the products that match your precise specifications.

The LJ Star Resource Center has many tools to help you and your company ensure sanitary standards.

T&C Stainless achieves all 3 with the help of LJ Star and TCI

Exceptional quality, industry-leading service and solutions, and world-class products. For more than 20 years, vessel maker and LJ Star customer T&C Stainless has delivered quality and innovation to the Biotech & Pharmaceutical industries.

They have grown from a garage-based business to an internationally recognized world leader by working with integrity and focusing on three main tenants – Quality, Pricing and Delivery. They work with each customer to set clear and achievable goals for all three, then work internally with their team of ASME Engineers and manufacturing specialists to deliver on those goals.

Also key to this process? Vendors that work the same way, with the same goals in mind. In LJ Star and its subsidiary Tank Components Inc. (TCI), T&C has found not just such a vendor but a true partner.

Quality

Saying you have quality components is all well and good, but with LJ Star and TCI, T&C has partners that can prove it. By using top-of-the-line materials in its ferrules, tank heads, manways, process lighting, sight glasses, clamps and more, and providing the traceable paperwork to prove standards compliance, T&C can meet and exceed the rigorous standards their customers require.

Pricing

T&C and TCI have partnered since T&C was founded, and LJ Star has worked with T&C since acquiring TCI. Together, the three companies have a well-established relationship that allows them to bring the maximum value to each project, ensuring that customers get additional value and superior quality. As much as price, T&C looks to add value to its products, and the LJ Star/TCI partnership has delivered that.

Delivery

Of course, a valuable, well-made vessel does a company no good if it’s held up because of supply issues. Here too, the partnership between the three companies has paid dividends. By being up-front, honest and setting clear expectations, the companies can work together to innovate and deliver the right solution to each issue and the best products for the end customer.

Learn more about this partnership and the gains it has brought to T&C Stainless in this Case Study.

LJ Star Sight Flow Indicators for industrial applications are the most common flow indicators style that enables visual observation of process flow through a pair of sight glasses mounted on a carbon steel body.

They are commonly used in industries that require a tool to monitor the speed and quality of liquid, gaseous products, or raw materials such as Chemical, Pharmaceutical, Food and Beverage, Agriculture, Marine and Industrial. With LJ Star Incorporated, you can be assured of high-quality industry-proven products that guarantee long-lasting use at an affordable cost.

What is a Flanged Sight Flow indicator?

A sight flow indicator is a body with one or more viewing windows, usually with gaskets, and a way to mount the indicator to the pipeline, such as flanged, threaded, or sanitary clamp connection. Flanged industrial sight flow indicators are often used in industrial applications between the API valve and tanker piping, allowing the operator to see fuel flow to or from tank.

LJ Star offers a full line of sight flow indicators to fit any processing application.

What is a Sight Flow Indicator?

A sight flow indicator is a tool used in a variety of processing plants to safely inspect the process material. When installed in process pipelines, sight flow indicators allow visual observation of the direction and rate of flow of liquid, powder, or gas process media, as well as the media’s color and clarity, through one or more observation windows. They consist of a glass column or two opposing windows with a means to mount the device to a pipeline.

What is a Sight Flow Indicator Used For?

The sight flow indicator is used for visual inspection by a human operator in a processing plant. Process fluids must be regularly inspected for characteristics such as clarity, color and foam or to confirm that there is proper flow in the pipeline. Sight flow indicators are also used to visually confirm conditions reported by instrumentation and to provide a backup in case of instrument failure or a power outage.

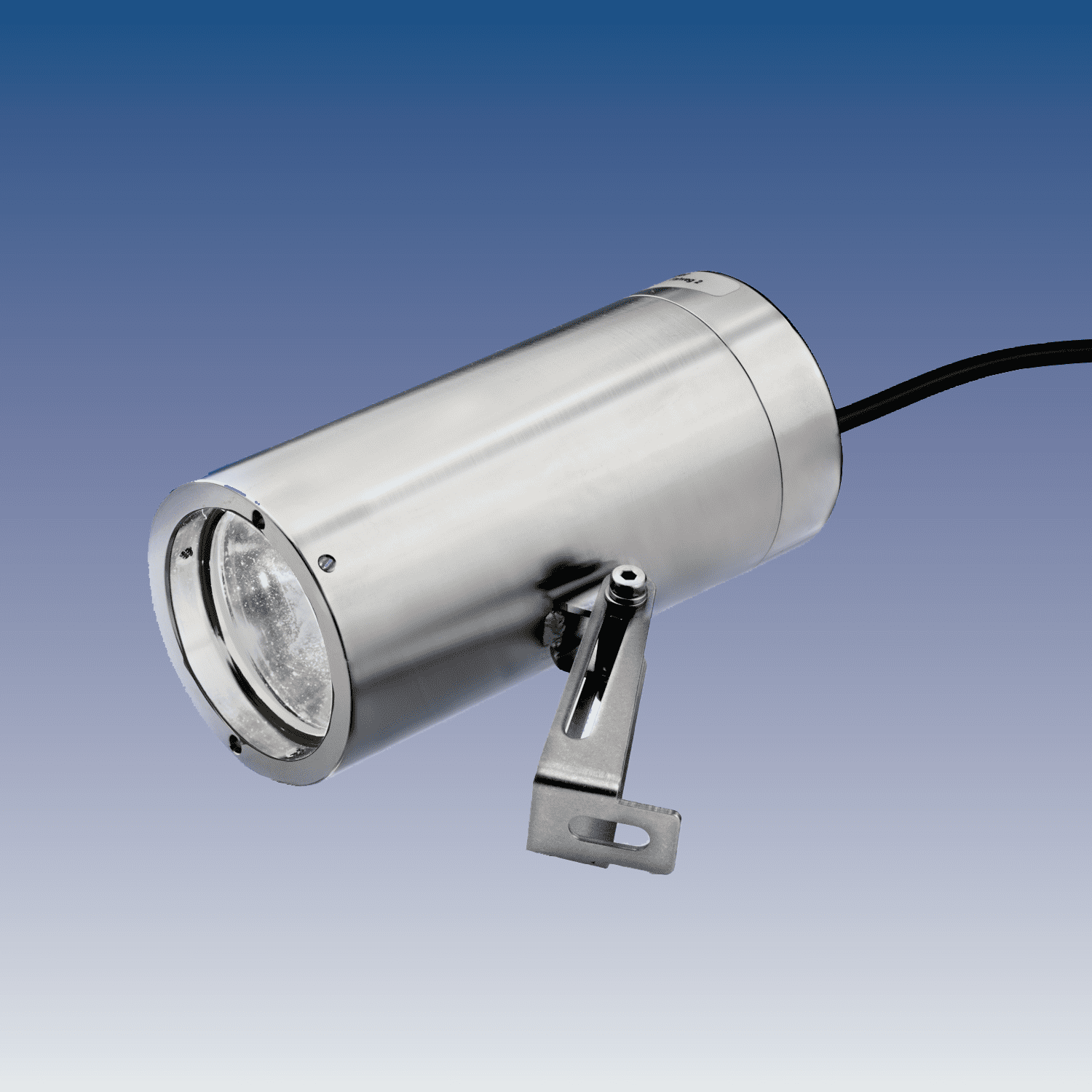

Explosion-proof process lighting solutions for industrial applications allow illumination in hazardous facility areas. Also referred to as EX lights, explosion-proof lights are suitable for illuminating processes in hazardous locations where combustible gases or vapors may be present, such as a critical processing line, pipeline, or vessel.

Plant managers know that you can’t control what you can’t see. That’s why sight glasses are installed throughout a system so that you can view what’s going on inside… but that isn’t enough. Without proper lighting, the interiors of your processing lines, vessels, and pipelines are often too dark for your operators to view critical process stages through a sight glass. Flashlights or other portable lights simply cannot provide sufficient lighting, and will often cause a glare to appear on the surface of the sight glass, making your visual inspections very difficult.

LJ Star’s weld-on and magnetic level gauges provide safe and accurate sight indication of fluid levels in a tank, process vessel or boiler.

What is a Liquid Level Gauge?

Liquid level gauges are industrial meters that are used to determine the level of a liquid in a process tank. Liquid level gauge calibration is used to ensure proper readings are obtained when using level gauges.

How Does a Magnetic Liquid Level Gauge Work?

Magnetic level gauges use magnetism to link the indicator in a gauge to a float inside of a vessel in order to accurately show the level of fluid within. As the position of the float changes, the indicator moves up or down by the same amount, meaning that the level in the measuring chamber will always be the same as the fluid level in the vessel itself.

Going to the Craft Brewers Conference in Colorado this week? Stop by booth #3838 for your personal demonstration of our new lights:

- Go green with LED technology

- 2x brighter than a traditional 100-watt halogen light

- See your process like never before for finer control

LJ Star is showcasing its entire line of sight windows, LED lighting and sanitary clamps at this year’s PackExpo (booth # SU-7125), September 27-29. You’ll be able to see our products, videos and even talk with our applications specialists about your specific facility.

Can’t go to the shows? Visit our Virtual Trade Show Booth right now! LJ Star has created its own virtual exhibit, filled with information on new products, links to videos and white papers. You can even chat with one of our applications experts when visiting the booth, via online chat.

Lumiglas Explosive LED Lights for Processing Applications

Learn More: Visit www.ljstar.com to see specs, download CAD files and view tutorials

Never Miss a Show Again – LJ Star Launches Interactive Virtual Trade Show Exhibit

Thinking about going to Pack Expo or Interphex but don’t have the time or travel budget? Still want to find out what’s new, or ask questions about new LJ Star technology?

There’s no substitute for face-to-face conversation, of course, but if that’s not possible LJ Star has created the next best thing – its new Virtual Trade Show Exhibit!

In process industries ranging from industrial, chemical, food/beverage or pharmaceuticals, it’s essential that products are processed in the safest environment possible in order to

comply with a wide variety of regulations. Lighting plays a critical role to safety, of course. In order to see critical processes inside your tanks and vessels, you need the most reliable lighting available. And reliability certainly begins with availability – if you can’t find new halogen bulbs to replace your existing halogens, it’s lights out for your process.

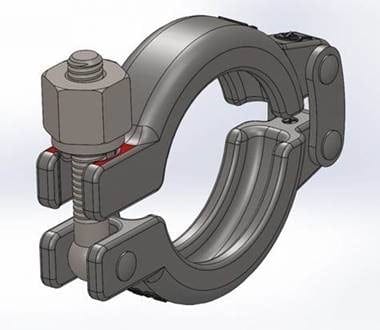

Twinsburg, OH – February 22, 2021 – LJ Star offers a line of Anti-Galling Clamps that are specially designed to prevent the adhesion of materials due to friction and to keep processes running smoothly. The full line of Anti-Gall Clamps is produced to the highest hygienic engineering standards and are constantly being updated based on customer feedback and industry requirements.

“If galling occurs on a sanitary clamp, the nut and bolt fuse together so the operator can’t easily remove the clamp,” explained LJ Star National Sales Manager Jeremy Sheldon. “Quite often, the operator would have to cut off the clamp to remove it. This would

Are you working in a highly explosive environment? Even the most demanding applications still require reliable process monitoring in order to keep operations safe and compliant. Without high-quality process viewing equipment, you could be putting your workers and products at risk.

Twinsburg, OH – January 26, 2021 – LJ Star (www.ljstar.com) announces that its patent-pending Clamp Type Sterile Visual Flow Indicator, or CT-SVFI, was awarded one of Processing Magazine’s 2020 Breakthrough Products Awards.

Processing’s annual Breakthrough Products Awards showcase innovate technologies that improve operations in the processing industry. Each year the magazine selects the 10 most significant product developments in the industry, recognized for helping end users better manage tough processing environments, achieve regulatory compliance, reduce unplanned downtime and drive overall profitability.

One of the best sight glass lights just got even better. The LJ Star LumiStar®1000, the world’s brightest compact sight glass luminaire, is now Intertek ETL approved and conforms to UL 2108; in Canada it conforms to CSA C22.2 #250.0.

What is the ETL Listed Mark?

Intertek ETL certifications serve as the benchmark for safety and performance in today’s processing equipment. The ETL Listed Mark indicates that a product has

As part of the company’s vision for the future, executives recognized that LJ Star had markedly changed from its historical beginnings in the market. LJ Star began in 1991 as a single-product distributor and has expanded its portfolio to become a multi-solution manufacturer of its own products, requiring that it change how it was positioned.

We’re all living through new experiences these days, and “attending” virtual trade shows is one of them. While we’ll miss seeing everyone in person at PackExpo 2020, LJ Star is preparing a wide range of demos and product highlights to feature our newest products.

Have you ever wondered how the food and beverage manufacturing companies keep their facilities clean? After all, food is one of people’s basic needs, and knowing where our food comes from makes us feel content with our choice.

When it comes to cleaning and sanitizing their liquid tankers and process vessels, the food and beverage processors face many challenges on a daily basis. Thus, they use a variety of tools to make sure they produce quality products, these include process vessel cameras.

A sight flow indicator gauges the direction and speed and flow of the process material. It is a product installed in a pipe that provides a visual aid to verify liquid flow for direction and accuracy.

Sight flow indicators never go out of style, but they do require occasional replacement, either as part of the facility’s overall maintenance plan or to repair damaged units. When installed in process pipelines, sight flow indicators allow visual observation of the direction and rate of flow of liquid, powder, or gas process media, as well as the media’s color and clarity, through one or more observation windows.

A hygienic bubble trap, or bubble trap, is a crevice-free and self-draining trap that can efficiently remove unwanted gas or air bubbles in process fluids. Bubble traps are specifically designed for chromatography applications, these hygienic bubble traps achieve higher concentrations of process fluids without providing crevices or other areas that where harmful bacteria can accumulate.

Fused sight glass is sometimes used to promote some brands of sight glasses based on the belief that greater fusion of glass to metal during the manufacturing process will produce a stronger finished sight glass for use in chemical and pharmaceutical processes.

Many processes take place in hazardous environments where explosive conditions may be present. For these applications, LED sight glass lights for explosion-proof lighting combines safe interior illumination and glare-free viewing.

Eliminate Clamp Galling

Eliminate Clamp Galling

Pharmaceutical applications require hygienic environments. Companies involved in pharmaceutical production must ensure tight controls on product purity through every stage of the development process, from manufacturing and quality control to packaging and shipping. Due to the tight restrictions that the FDA and other

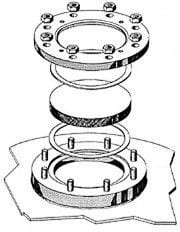

Sanitary fittings – also called hygienic fittings – can keep your systems locked down and clean while providing a quick disconnect for faster disassembly and maintenance. However, sanitary fittings and system connections must be properly installed and maintained in order to keep your systems clean, efficient and safe.

Sanitary fittings – also called hygienic fittings – can keep your systems locked down and clean while providing a quick disconnect for faster disassembly and maintenance. However, sanitary fittings and system connections must be properly installed and maintained in order to keep your systems clean, efficient and safe.

Magnetic level gauges use magnetism to link the indicator in a gauge to a float inside of a vessel in order to accurately show the level of fluid within. As the position of the float changes, the indicator moves up or down by the same amount, meaning that the level in the measuring chamber will always be the same as the fluid level in the vessel itself.

Magnetic level gauges use magnetism to link the indicator in a gauge to a float inside of a vessel in order to accurately show the level of fluid within. As the position of the float changes, the indicator moves up or down by the same amount, meaning that the level in the measuring chamber will always be the same as the fluid level in the vessel itself.

Eliminate threads and gasket compression problems that lead to contamination with this innovative new solution from LJ Star. Designed for hygienic/sterile applications in pharmaceutical, food/beverage, brewery and biotech industries, the new Clamp Type Sterile Visual Flow Indicator, or CT-SVFI, uses a patent-pending design to prevent the o-ring and gasket compression issues that lead to contamination associated with conventional screwed or threaded fittings.

Eliminate threads and gasket compression problems that lead to contamination with this innovative new solution from LJ Star. Designed for hygienic/sterile applications in pharmaceutical, food/beverage, brewery and biotech industries, the new Clamp Type Sterile Visual Flow Indicator, or CT-SVFI, uses a patent-pending design to prevent the o-ring and gasket compression issues that lead to contamination associated with conventional screwed or threaded fittings.

Sanitary sight glasses allow engineers, plant managers, and technicians alike to look inside their equipment without contaminating their systems. Through superior hygienic designs, these types of sight glasses have no crevices or intrusive gaps that could harbor harmful bacteria.

Sanitary sight glasses allow engineers, plant managers, and technicians alike to look inside their equipment without contaminating their systems. Through superior hygienic designs, these types of sight glasses have no crevices or intrusive gaps that could harbor harmful bacteria.

Sanitary fittings, also known as sanitary clamps or hygienic clamps, are clamping devices used to seal two ferrules together in a manner that meets the high hygienic standards of regulatory agencies. Often quick to install, these fittings create secure connections between your equipment without creating sites that can harbor bacteria.

Sanitary fittings, also known as sanitary clamps or hygienic clamps, are clamping devices used to seal two ferrules together in a manner that meets the high hygienic standards of regulatory agencies. Often quick to install, these fittings create secure connections between your equipment without creating sites that can harbor bacteria.

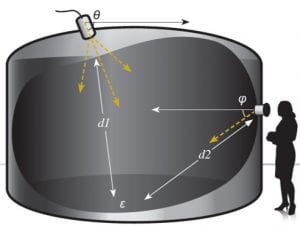

Undiffused light can reveal a large number of surface imperfections in stainless steel products that diffused light does not. By analyzing these differences, diffused light has been found to have less variability in the intensity of reflected light, making it ideal for sight-based applications. If you’re using a sight glass to monitor your tanks or systems, you’re going to want to work with diffused light.

Undiffused light can reveal a large number of surface imperfections in stainless steel products that diffused light does not. By analyzing these differences, diffused light has been found to have less variability in the intensity of reflected light, making it ideal for sight-based applications. If you’re using a sight glass to monitor your tanks or systems, you’re going to want to work with diffused light.

Since the interior of your vessels and pipelines are often too dark for you to see through a sight glass, exterior lighting must be used to illuminate the important stages of your systems. Typical flashlights aren’t powerful enough and often create distracting glares on the sight glass. That’s why mounting lights, or luminaires, must be affixed to your equipment if you want to accurately look through a sight glass and monitor your systems.

Since the interior of your vessels and pipelines are often too dark for you to see through a sight glass, exterior lighting must be used to illuminate the important stages of your systems. Typical flashlights aren’t powerful enough and often create distracting glares on the sight glass. That’s why mounting lights, or luminaires, must be affixed to your equipment if you want to accurately look through a sight glass and monitor your systems.

Mounting lights, or “luminaires”, are required in most sight glass applications in order for operators to be able to accurately see what’s going on inside a vessel or pipeline. Where flashlights and other commercial lighting solutions fail, industry-grade mounted lights can provide direct, high-powered illumination that can light up even the darkest environments.

Mounting lights, or “luminaires”, are required in most sight glass applications in order for operators to be able to accurately see what’s going on inside a vessel or pipeline. Where flashlights and other commercial lighting solutions fail, industry-grade mounted lights can provide direct, high-powered illumination that can light up even the darkest environments.

Explosion-proof process lighting solutions for industrial applications allow illumination in hazardous facility areas. Also referred to as EX lights, explosion-proof lights are suitable for illuminating processes in hazardous locations where combustible gases or vapors may be present, such as a critical processing line, pipeline, or vessel.

We have recently learned that inferior gauge glass, with a historically common industry name, from an overseas supplier has entered the North American market and does not meet accepted standards of safety and performance.

We have recently learned that inferior gauge glass, with a historically common industry name, from an overseas supplier has entered the North American market and does not meet accepted standards of safety and performance.

Beer is one of the oldest and the most largely consumed alcoholic beverages in the world. This all-time favorite brew has been a staple at sporting events, social gatherings, and family barbecues for generations. During the past few years, craft beers have created quite a buzz among younger consumers seeking a more unique palette than their parents’ traditional beer. Craft breweries have experienced unprecedented growth by bringing an almost endless variety of beer styles to the market. In fact, the overall global beer market is expected to reach $685 billion by 2025.

While inherently resistant to corrosion, sight glasses can begin to corrode under the right circumstances, particularly if the wrong material is spec’d for the application. If a sight glass happens to corrode, it becomes increasingly vulnerable to sight glass failure. When glass fails, it is often sudden and catastrophic, damaging your system, putting workers at risk, and causing unplanned downtime. That’s why it’s important to understand the dangers of sight glass corrosion and failure so that you can adequately prepare for them… and avoid a costly disaster.

The purpose of a sight glass is to allow plant managers and engineers to look inside of their systems without disrupting the environment within. Often referred to as viewing glasses, they offer you a way to see the levels of liquids or gases that are traveling through a critical point of your design, monitor pressure changes, and virtually anything else that sight glass windows could allow you to do. With their widespread use, sight glasses have become critical to operations such as steam pipelines, chemical processing, pharmaceutical processing, and food processing.

The purpose of a sight glass is to allow plant managers and engineers to look inside of their systems without disrupting the environment within. Often referred to as viewing glasses, they offer you a way to see the levels of liquids or gases that are traveling through a critical point of your design, monitor pressure changes, and virtually anything else that sight glass windows could allow you to do. With their widespread use, sight glasses have become critical to operations such as steam pipelines, chemical processing, pharmaceutical processing, and food processing.

What is a sight flow indicator?

A sight flow indicator provides a window into a process pipeline that allows operators a visual means of verifying liquid flow and flow direction. Simple and low-cost, it also allows operators to observe the color, clarity, consistency, viscosity and other characteristics of process fluids.

The basic description of a sight flow indicator is a glass column or two opposing windows with a means to mount the device to a pipeline. Bodies or heads in a tubular style are usually constructed out of a specific metal. Windows are made from special glass discs in a gasketed assembly, glass windows fused in a metal frame, or tubular glass. Occasionally polymer windows are used.

How does a sight flow indicator work?

A sight flow indicator gives the operator a window to observe how a process fluid moves through the pipeline.

At a basic level, how a sight flow indicator works is simple: just look through the window to observe the flow in a pipeline. Actually, there are complexities in the many types of indication and construction of the equipment. Each style of indicator works a little differently.

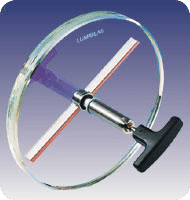

Vote for LumiFlo®!

We’re so excited to announce that the LumiFlo® LED light has been nominated for a 2019 Flow Control Innovation Award.

The LumiFlo® LED Light is a first-to-market, exclusive patent pending LJ Star product that is designed to improve the lighting of full view sight flow indicators in process fluid lines. It easily attaches to most inline full view sight flow indicators in process fluid lines, allowing operators to clearly see color, flow and particles moving through the sight glass in order to visually inspect product quality, clarity, viscosity and consistency.

Thanks to all who stopped by to see us at the recent Interphex and Craft Brewing shows. We hope you enjoyed talking to our process observation experts and learned a few things about our products, as well.

Join us in the Rocky Mountain State April 8- 11th for the Craft Brewer’s Conference, the number one showplace in North America for concentrated, affordable brewing education and idea sharing to improve brewery quality and performance.

![]() We’ll see all the sights and take in a show… INTERPHEX is the premier pharmaceutical, biotechnology, and device development and manufacturing event where you can “Experience Science through Commercialization.”

We’ll see all the sights and take in a show… INTERPHEX is the premier pharmaceutical, biotechnology, and device development and manufacturing event where you can “Experience Science through Commercialization.”

Join over 11,000 global industry professionals and 650+ leading suppliers, including L.J. Star, for demonstrations, and networking events to leverage quality, efficiency and cost effectiveness in today’s ever-changing pharma market.

Improperly specified, installed or maintained sight glasses can represent the weakest link in a processing system. The wrong glass or materials used will limit observation, require extra maintenance and replacements, and even fail under pressure with catastrophic results – since glass can fracture at 5 miles/second!

Keeping a Firm Grip on Sanitary Clamp Safety

For pharmaceutical and biotech companies, maintaining sterile process control is an ever-increasing challenge – one that can lead to cross-contamination, short term loss of product, long term drug shortages, lawsuits and even loss of life should sterile process be breached.

Keeping an Eye on Sight Glass Safety

If improperly specified, installed or maintained, sight glasses can be the weakest link in a processing system because they can limit observation capabilities, require frequent maintenance or replacement, or make it difficult to illuminate the vessel in which they’re installed.

In our efforts to continually improve our products we are introducing a change to the Domed Hexagon Nut used to tighten our range of clamps. These nuts are used to replace the Wing Nut in certain applications. The existing Domed Hexagon Nut, we currently supply, will become obsolete to be replaced by the new Hexagon Flat Nut.

In our efforts to continually improve our products we are introducing a change to the Domed Hexagon Nut used to tighten our range of clamps. These nuts are used to replace the Wing Nut in certain applications. The existing Domed Hexagon Nut, we currently supply, will become obsolete to be replaced by the new Hexagon Flat Nut.

Aarash Navabi, CPIP, Director of Research + Development, Research Dynamics, Massachusetts Division of L.J. Star, participates on several critical ASME Bioprocessing Equipment (BPE) Committees, the Surface Finish Subcommittee, the Polymers Subcommittee and is leading another Task Group for BPE. At meetings held in San Diego, California in May 2018, Aarash reported on a variety of committee discussions and decisions that drive the processing industry.

Gabe Montgomery, Engineering Manager, Tank Components Industries, an L.J. Star subsidiary located in Springfield, Missouri, is one of several L. J. Star engineers to serve on important ASME Bioprocessing Equipment (BPE) Committees. His work on the committee is part of the company’s contribution to advancing the technologies that shape our industry and to keep our customers informed on changes in the field. BPE held several meetings in San Diego, California in May 2018, and Gabe reports back on what he heard:

Michael Bosley, one of L.J. Star’s Product Support Specialists, took part in ASME Bioprocessing Equipment (BPE) Committee Meetings, held May 7-10, 2018, in San Diego, California. As a leading supplier to the biotechnology industry, we take our responsibility to participate in advancing the industry very seriously. By participating in the work of these committees, we hope to stay on the leading edge of evolving technologies; at the same time, we want to share updates on the topics these committees are weighing with you, so you can stay up to date on industry trends.

Michael Bosley, one of L.J. Star’s Product Support Specialists, took part in ASME Bioprocessing Equipment (BPE) Committee Meetings, held May 7-10, 2018, in San Diego, California. As a leading supplier to the biotechnology industry, we take our responsibility to participate in advancing the industry very seriously. By participating in the work of these committees, we hope to stay on the leading edge of evolving technologies; at the same time, we want to share updates on the topics these committees are weighing with you, so you can stay up to date on industry trends.

A “Light” Recipe for Craft Brewing Success

Halogen lamps were once the standard choice for craft brewers’ vessel sight glass lighting. However, a new generation of LED luminaires is growing in popularity for this application. Consider these questions to decide whether it’s time for your brewery to invest in making the switch to LEDs.

Why METAGLAS® Is Considered the Safest Sight Glass in the World

Since it was developed in the 1970s, METAGLAS® has been known as the safest sight glass in the world. A number of chemical and manufacturing companies collaborated to create METAGLAS, and to establish the standard with which it complies and by which all other sight glass is measured, a standard now called DIN7079.

Using sight glasses is essential in the production of pharmaceuticals, as is maintaining the functionality and cleanliness of those sight glasses. The good news is that a wide variety of sight glass accessories are available to assist pharmaceutical manufacturing personnel in the production of pure, high-quality product in every batch.

Using sight glasses is essential in the production of pharmaceuticals, as is maintaining the functionality and cleanliness of those sight glasses. The good news is that a wide variety of sight glass accessories are available to assist pharmaceutical manufacturing personnel in the production of pure, high-quality product in every batch.

For pharmaceutical manufacturers, maintaining the cleanliness of their facilities, especially their stainless-steel process vessels, is Job #1. A UV light for your sight glass can help, as UV light can be used to inspect and verify SIP and CIP procedures have done an adequate job.

Vessels must be cleaned and sterilized thoroughly between each product batch. This is important to prevent contamination from previous batches or residual cleaning agents from adulterating the product. Depending on the type of drug being produced, an inadequately cleaned vessel could potentially force the facility to quality reject millions of dollars’ worth of compromised product.

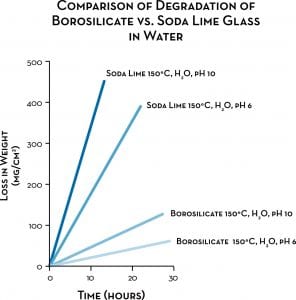

As hot water passes through ground coffee beans, it extracts flavors, colors, and stimulants that make mornings more livable for many of us. When it comes to pharmaceutical processing, however, extraction can be a bad thing, as leaching from process system surfaces can extract unwanted elemental impurities.

The Chem Show is where engineers, plant managers and other CPI personnel come together to see the latest equipment & technology, meet product experts, and discover new ways to optimize their plant operations. Bringing together more than 5,000 industry professionals and 300 exhibiting companies, the Show is the largest North American event exclusively focused on the processing of fluids, powders and gases. Held every odd year since 1915, the Chem Show has a proven track record of helping the CPI meet the ongoing demand for faster, smarter, cleaner, and more efficient processing facilities.

The Chem Show is where engineers, plant managers and other CPI personnel come together to see the latest equipment & technology, meet product experts, and discover new ways to optimize their plant operations. Bringing together more than 5,000 industry professionals and 300 exhibiting companies, the Show is the largest North American event exclusively focused on the processing of fluids, powders and gases. Held every odd year since 1915, the Chem Show has a proven track record of helping the CPI meet the ongoing demand for faster, smarter, cleaner, and more efficient processing facilities.

Don’t forgot to stop by booth 431 while you are there!

The many ratings and standards bodies can be a confusing alphabet soup of acronyms… ATEX, UL, NEC, IEC, IP and NEMA. When is ATEX the right one?

If you are considering an ATEX explosion-proof light for your sight glass, then you already know that a light with an ATEX rating will be safe to operate in a potentially explosive atmosphere.

First, forget about IP and NEMA ratings. Those define housings. For example,

A common question that I hear is, “what is the first-indication flow rate?”

A common question that I hear is, “what is the first-indication flow rate?”

Sight flow indicators are a fail proof means of observing flow within a process pipeline. To make it easier to see the flow, often a mechanical indicator is added behind the window… a spinning rotor for example. What people are asking is, what is the minimum flow needed to move the indicator?

For my pharmaceutical and biotech customers, sanitary clamps (also called hygienic clamps) keep systems clean while allowing quick disconnects. However, making reliable process system connections is anything but routine. If it isn’t done just right,

For my pharmaceutical and biotech customers, sanitary clamps (also called hygienic clamps) keep systems clean while allowing quick disconnects. However, making reliable process system connections is anything but routine. If it isn’t done just right,

What is a sight glass? Definitions for common sight glass terms.

A sight glass, which can also be referred to as a sight port window or a sight window, is an observation window that allows you to look at fluid stored under high temperatures, extreme pressures, and other extreme environmental conditions. They are typically made of robust glass substrates that are used to analyze conditions in industrial equipment, chemical reactors, and more.

Sight glasses are used in industries ranging from refineries to craft breweries. They allow you to look inside equipment without having to worry about explosions, corrosion, or other types of damage. Perhaps because of their widely-varied applications, sight glasses are called by different names. Broadly speaking, a sight glass is any kind of window on a process vessel

Why Preventing Sanitary Clamp Galling Is Crucial to Product Purity

All makers of pharmaceuticals and biotechnology products have many concerns in common, but none is more critical than maintaining tight control over product purity during manufacturing and packaging. For example, if contamination were to compromise the integrity of a single batch of insulin, it could easily mean a loss of hundreds of thousands or millions of dollars in revenue to the manufacturer.

A sight glass seems pretty straightforward: a fitting with a window installed on the top or side of a vessel that you can look through and see what’s going on. Simple, right?

A sight glass seems pretty straightforward: a fitting with a window installed on the top or side of a vessel that you can look through and see what’s going on. Simple, right?

Not so fast. There is a wrong way to do anything, and choosing the wrong type of glass for a sight glass can have bad

The medicinal use of cannabis is becoming normalized in a growing number of states. Some of the products used include botanical oils. The botanical oil extraction process relies on pressure and solvents generally recognized as safe by the FDA. CO2 and hydrocarbon solvents such as butane or propane are the most common. Systems that use nButane work at relatively low pressures in the range of 80 to 150 psi. CO2 systems operate at higher pressures up to 5000 psi. Obviously, a failure at these pressures can be dangerous to workers, and natural gas products also carry the risk of fire and explosion.

The medicinal use of cannabis is becoming normalized in a growing number of states. Some of the products used include botanical oils. The botanical oil extraction process relies on pressure and solvents generally recognized as safe by the FDA. CO2 and hydrocarbon solvents such as butane or propane are the most common. Systems that use nButane work at relatively low pressures in the range of 80 to 150 psi. CO2 systems operate at higher pressures up to 5000 psi. Obviously, a failure at these pressures can be dangerous to workers, and natural gas products also carry the risk of fire and explosion.

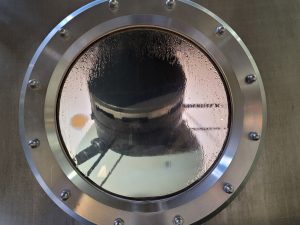

Like other critical components of getting the perfect brew, conical fermenters need to be closely observed. Fermentation is part art, which means you need to involve your senses: seeing, smelling, tasting. It’s also part science, which means that you need a way to confirm that each stage of the process is going according to plan: that the cleaning solution is fully rinsed, that there is no cross batch contamination, etc. In short, you need a sight glass window on your vessel, and a light to illuminate its interior.

Conical fermenter sight glass lights come in various types and configurations. In my post today I’ll review some of your options, so you can choose the optimal light for your situation. By the way, although I’m focusing on fermenters, which may be conical or straight, the same advice will apply to any brewing equipment vessel, including mash lauter tuns, finishing tanks, and the like.

Conical fermenter sight glass lights come in various types and configurations. In my post today I’ll review some of your options, so you can choose the optimal light for your situation. By the way, although I’m focusing on fermenters, which may be conical or straight, the same advice will apply to any brewing equipment vessel, including mash lauter tuns, finishing tanks, and the like.Food and Beverage Application Experts in the $738 billion food and beverage manufacturing industry know that, for consumers, taste begins with the eyes. This is especially true with beverages, for whom hue, clarity, cloudiness, transparency, opacity and foam are very tightly controlled. Such the domain of the processing engineer, who depends on the sight glass and associated lighting to observe the process media.

How to Size a Sight Glass Light for a Process Vessel?

Ah, the world of lighting used to be so simple. When you needed to illuminate the interior of a process vessel or tank, you selected a halogen light by its watts. Typically you used a 50 watt light because that’s what the manufacturers commonly offered. If that wasn’t bright enough, then you used a 100 watt light. It got hot, but you didn’t have much choice. The decision for your sight glass light was simple.

I have a tank and need a sight glass. What are my options? Although this may seem like an innocuous question… many factors come into play. While the choice is clear for some customers, there are many more for whom this choice is anything but clear.

I have a tank and need a sight glass. What are my options? Although this may seem like an innocuous question… many factors come into play. While the choice is clear for some customers, there are many more for whom this choice is anything but clear.

Sight glasses allow you to safely observe processes inside your tanks, vessels, pipes, and reactors. It is a window that allows operators to inspect the process media, observe reactions, observe the functioning of mixing equipment, verify the presence or absence of media, see liquid level, etc. It consists of metal, glass, and gasket components. In order to ensure optimal performance, a variety of factors need to be considered. Here are 5 critical things to consider when specifying a sight glass for your process.

CHEM Show 2015, the trade show dedicated to the Chemical industry, is headed back to the Javits Center in New York City from November 17 through 19. Along with more than 300+ chemical industry professionals, representatives from L.J. Star will be on hand to meet and greet our long-time friends (and prospective friends!) in the chemical industry.

Sight Glass Maintenance Tips from L.J. Star Incorporated

Ready to roll…. The time and effort deciding where and when to show has been a challenge for some time. Making the right choices to promote oneself and stay on top of industry trends, demands and forecasting the needs of customers is critical in any business. So when an opportunity arises you’d be a fool to pass it by. And this week LJ Star, Inc will be taking advantage of such an opportunity by showing at the American Manufacturing Summit, February 29- March 1, 2016.

CHEM Show 2015, the trade show dedicated to the Chemical industry, is headed back to the Javits Center in New York City from November 17 through 19. Along with more than 300+ chemical industry professionals, representatives from L.J. Star will be on hand to meet and greet our long-time friends (and prospective friends!) in the chemical industry.

Recently, managers at a major U.S. pharmaceutical manufacturer were reminded of the importance of constant vigilance in their containment systems when they discovered leaks in sanitary clamp connections that forced them to scrap costly process media.

In a pharmaceutical or biotechnology setting, process equipment and piping are connected using a stainless steel sanitary clamp that forces together two ferrules, whose raised lips on the pipe ends facilitate a tight connection. Sanitary fittings are made specifically for pharmaceutical applications, where joint cleanliness and access are of paramount importance. Clamps allow quick disassembly for cleaning and sterilization. To prevent the formation of shelves or pockets that can harbor bacteria the ferrules, gasket and clamp must also provide a non-protruding, recess-less product contact surface.

INTERPHEX 2014, the trade show dedicated to the pharmaceutical industry, is headed to the Javits Center in New York City from March 18 through 20. Along with more than 12,000 pharmaceutical industry professionals, representatives from L.J. Star will be on hand to meet and greet our long-time friends (and prospective friends!) in the pharmaceuticals industry.

Say green energy, and the first words that spring to most minds are likely either solar power or wind power. But there’s another important player in the alternative energy marketplace─biogas generation.

Biogas is produced when organic matter breaks down in the absence of oxygen. It’s produced by anaerobic digestion by bacteria or fermentation of biodegradable materials such as manure, sewage, municipal waste, or plant material. Like solar and wind power, it’s a renewable energy source. It can be used as a fuel in a variety of applications; when cleaned and compressed, it can power motor vehicles.

“Learn the Secret of Sight Glass Strength” is a recent video from L.J. Star that outlines the precision process of fusing borosilicate glass to a stainless steel ring, then cooling it carefully to create a METAGLAS® sight glass window. Once the process is complete, the ring compresses the glass continuously, which gives it its exceptional tensile strength, preventing dangerous ruptures or fragmentation for greater reliability and safety. By combining the transparency of glass with the strength of steel, METAGLAS virtually eliminates the possibility of a sudden, unexpected rupture, and any crack that might develop, at worst, may slightly affect visibility. In addition to the unsurpassed pressure and impact resistance, the metal frame provides rigidity to prevent breakage if bolts are tightened unevenly during installation. METAGLAS products have been tested and approved by safety testing departments of several major chemical and other companies under a variety of conditions, most exceeding those normally encountered in practice.

For a process engineer, being smooth means more than knowing which wine to order in a fancy restaurant. In plant operations, the surface finish of a process vessel, piping, and related components can have profound effects on how well a fluid system performs. Surface roughness can affect fluid flow resistance (friction), adsorption/ desorption, bacteria growth, the build-up of chemicals from a process fluid, corrosion formation, pressure drop, etc. Ultimately, the smoothness of a surface finish can affect service life and maintenance costs. In a sight glass, for example, the surface roughness of both the glass and the metal mounting ring are critical for achieving a good seal in the installation.

Any plant operator can tell you that an innocent-looking set of pipes can conceal nasty secrets, some as petrifying as the monster hiding in the plumbing in a Harry Potter movie. A sight flow indicator is a good way to discover what’s lurking within.

These simple, low-cost devices provide a visual means of verifying liquid flow for direction and approximate rate, and also to observe the color and clarity of process fluids. The body of a sight flow indicator is equipped with one or more viewing windows, usually with gaskets, and a way to mount the indicator to the pipeline, such as a flanged, threaded, or sanitary clamp fitting. They are available to fit standard pipe sizes ranging from ¼-inch to 16 inches and carry ANSI pressure ratings.

An industrial sight glass is a critical part of virtually any type of process equipment because it allows for visual inspection of industrial and pharmaceutical processes. Luminaires are often used in conjunction with an industrial sight glass to illuminate tank and pipe interiors.

In a system made primarily of metal, like a pressure vessel, the weak spots are generally sealing joints and glass. However, an industrial sight glass is a highly engineered product. Although different brands of industrial sight glass might look alike, differences in their specs have tremendous impact on worker safety, sterile processes, and maintenance costs. In industrial applications, sight glasses are often subject to extremes of pressure, temperature, thermal shock, caustics, abrasion, or impact. Choosing the right industrial sight glass depends on taking all of these considerations into account.

Is your sight glass tough enough to handle “The Big Six” challenges?

Sight glass failures can be extremely dangerous. A sight glass that fails catastrophically has the potential for severe operator injury or death, as well as costly downtime and product losses. Even minor cracks, scratches or abrasions can create weakness within the sight glass, which will most likely lead to failure. In normal use, sight glasses are regularly subjected to forces involving extremes of pressure, temperature, thermal shock, caustics, abrasion, or impact.