What are the Effects of Undiffused and Diffused Light on Stainless Steel?

Posted by LJ Star Undiffused light can reveal a large number of surface imperfections in stainless steel products that diffused light does not. By analyzing these differences, diffused light has been found to have less variability in the intensity of reflected light, making it ideal for sight-based applications. If you’re using a sight glass to monitor your tanks or systems, you’re going to want to work with diffused light.

Undiffused light can reveal a large number of surface imperfections in stainless steel products that diffused light does not. By analyzing these differences, diffused light has been found to have less variability in the intensity of reflected light, making it ideal for sight-based applications. If you’re using a sight glass to monitor your tanks or systems, you’re going to want to work with diffused light.

Stainless steel is the go-to material for many industrial applications due to its superior chemical resistance and mechanical properties. As such, stainless steel is perfect for the harsh environment of a chemical or pharmaceutical tank. From food and beverage to pharmaceutical manufacturing, industries rely on stainless steel tanks to house liquids and gases for their fluid-based processes.

Staying Operational

To maintain your systems, tanks must be regularly inspected and cleaned. As they are used and cleaned, they need to be properly inspected to determine if all contaminants have been removed. High-quality tank lighting is extremely important to these inspections, allowing operators to properly determine the state of system operations and see if any contaminants are present. Timely, efficient inspections can help to catch and prevent the following:

- System blockage

- Fluid contamination

- System leakage

- Equipment malfunction

- Unplanned shutdowns

That’s why proper lighting is critical to any operations involving stainless steel tanks. Halogen lights have been the go-to source for sight glass illumination for some time now, and with good reason. Halogen lights are inexpensive, easy to get, and can be used in a variety of sight glass applications. That said, there are some disadvantages with halogen lights, including:

- Low energy efficiency

- Eye fatigue in operators

- Short bulb life

- Easily damaged filaments

Even considering the above, halogen lights are still great for many applications. However, if you want an even better product, light emitting diodes (LEDs) are the way to go.

As LED technology has evolved, LED tank lights have become more common. LED lights are brighter, produce less heat, and consume less power than halogen lights. As the use of LED lights has increased, so has the number of false detections of contaminants. This is mostly due to an incorrect use of the lights rather than a technological issue. That’s because this problem comes from LEDs producing undiffused light, which can reveal surface imperfections in the stainless steel tanks. Even to the most trained eye, these imperfections can interfere with an operator’s visual analysis.

This happens partially because of the small sizer of the LED and because your LED light is effectively acting as a spectral light source. The LED’s smaller size causes it to produce what’s known as hard light, which is light that causes shadowing and masking to occur. These effects further exaggerate any scratches or other surface features of your steel. This is intensified even more from the spectral light of the LED, which makes the light reflected from the stainless dependent on the angle of the light source and the angle the viewer is to the surface. This means that any surface imperfections perpendicular to the light source will be brighter than the surrounding material.

A Closer Look

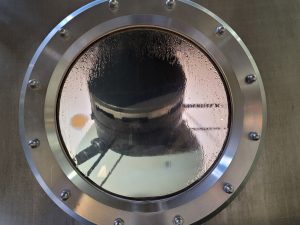

By conducting a light analysis, L.J. Star was able to further investigate the effect that undiffused light has on stainless steel. We photographed the illumination of both undiffused light and diffused light on a piece of stainless steel that was polished with an Ra of less than 20 µIn (0.5µ). To keep the tests standardized, the intensity of the light, the position of the stainless, and the camera settings were all kept the same in both cases. The photographs had such a sharp contrast between them that even a novice could spot the differences. Under the illumination of undiffused light, the stainless steel was dark and showed numerous scratches, while the diffused light brightened the steel with a mirror-like finish.

So are we forced into this tradeoff? Does the higher efficiency and capabilities of LED lights come at the cost of less accurate inspections? At L.J. Star, we know that that is simply unacceptable.

That’s why we’ve come up with an easy and effective solution to the problem. The goal is to still use LED lights over halogen lights due to their superior capabilities, so by equipping LEDs with a diffuser, we can correct their visual issues with stainless steel while retaining all of its positive properties.

Better Lighting

A diffuser is a translucent or semi-transparent cover that causes a light to spread out or scatter, allowing you to control the brightness of your light. This also causes it to emit a soft light relative to the lamp being used. In industrial sight glass applications, diffused light will cause the intensity of any light reflected by the stainless to reach more acceptable levels between imperfections and the rest of the material. It will also make the light source relatively large when compared to the surface features, getting rid of both shadowing and masking.

Along with the right diffuser, L.J. Star offers a number of LED lights that can illuminate your sight glass applications, available in explosion-proof designs that are environmentally sealed and made not to supply a spark. Our LEDs offer brighter light, higher energy efficiencies, less maintenance/replacement costs, and a longer life. Available up to 3000 lumens, these LED lights can illuminate even the toughest applications, with the energy efficiency that you need to keep your costs low and your margins high.

If you want to learn more about how different types of light affect your sight-based applications, click here.