Recently, managers at a major U.S. pharmaceutical manufacturer were reminded of the importance of constant vigilance in their containment systems when they discovered leaks in sanitary clamp connections that forced them to scrap costly process media.

In a pharmaceutical or biotechnology setting, process equipment and piping are connected using a stainless steel sanitary clamp that forces together two ferrules, whose raised lips on the pipe ends facilitate a tight connection. Sanitary fittings are made specifically for pharmaceutical applications, where joint cleanliness and access are of paramount importance. Clamps allow quick disassembly for cleaning and sterilization. To prevent the formation of shelves or pockets that can harbor bacteria the ferrules, gasket and clamp must also provide a non-protruding, recess-less product contact surface.

Usually the connections are routine. However, this manufacturer had equipment that was originally used in different plants located in different regions of the world. As a result, some of the connections were mis-matched: one side had a ferrule that met ASME-BPE (Bioprocessing Equipment) standards, but the other side had ferrules made to a different standard. Slight differences in their specifications made alignment and sealing a challenge through pressure and process temperature changes. Managers noticed that some clamps weren’t able to perfectly seal the ferrules, and the resulting leaks forced managers to discard entire batches of process media because there was no way to prove to the FDA that no contamination had occurred.

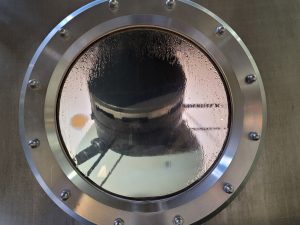

In their search for a solution to their mismatched ferrule problem, managers devised a torture test for sanitary clamps. Over two months, they tested six different brands of clamps. Clamp after clamp failed their stringent connection-point leakage tests under heat and pressure. The only clamp able to pass the manufacturer’s testing protocol was the Advanced Couplings clamp, distributed exclusively in North America by L.J. Star. These stainless steel clamps are made from investment castings to produce a high quality, precision fit assembly. The secret is the clamp’s unique “Omega” profile, which pushes the ferules into alignment with high clamping efficiency.

In a global industry, the problem of integrating equipment made to different specifications is increasingly common. To learn more about how the right sanitary clamp design can assure reliable connections, see the SlideShare presentation titled “Must-Have Information about Sanitary Fittings.”