Using sight glasses is essential in the production of pharmaceuticals, as is maintaining the functionality and cleanliness of those sight glasses. The good news is that a wide variety of sight glass accessories are available to assist pharmaceutical manufacturing personnel in the production of pure, high-quality product in every batch.

Using sight glasses is essential in the production of pharmaceuticals, as is maintaining the functionality and cleanliness of those sight glasses. The good news is that a wide variety of sight glass accessories are available to assist pharmaceutical manufacturing personnel in the production of pure, high-quality product in every batch.

Wipers

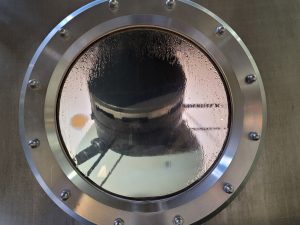

Sight glass wipers aid visibility by cleaning the inside glass surface of light ports and sight ports. Wiper assemblies must be constructed of high-grade stainless steel with either Teflon or silicone blades and work in conjunction with a spray ring or set of spray nozzles. They come in two types.

The Type I manual wipers require a bore-hole through the sight glass. They can operate at temperatures as high as 220 degrees F and under pressures as high as 90 psi.

When a higher-pressure sight glass requires cleaning, the Type II manual wiper, in conjunction with a DIN28120 sight glass, must be used. Type II wipers require a threaded bore hole through the sight glass cover and weld pad for proper installation. Type II wipers can operate at temperatures of up to 428 degrees F and pressures as high as 235 psi.

Sight glass wipers can be motorized and automated. Constructed in both explosion-proof and non-explosion-proof models, the explosion-proof models are rated to EEx d IIC T5 (Zones 1 & 2 and 21 & 22) and are able to operate in ambient temperatures ranging from minus 4 degrees F to 122 degrees F. Motors generally fit specific types, sizes, and brands of wipers, and operate on a variety of direct and alternating currents.

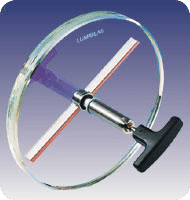

Spray Rings and Nozzles

Sight glass wipers operate together with a spray ring or spray nozzles to achieve effective cleaning. The spray ring must fit ANSI flange connections for use in intermittent or continuous pressure-cleaning operations. For versatility, the ring delivers a variety of spray media, including fluid or air. The rings can include varying numbers of spray nozzles depending ring diameter. They are also available in different materials and sizes for diverse applications. Materials used include carbon steel, stainless steel, Hastelloy, and other alloys. Temperature and pressure ratings vary depending on the ring material and ANSI-rating.

Timers

Sight glass light timers are convenient where illumination is limited to a specific period. A timer switches lights on and off automatically, reducing power consumption and heat build-up, and providing improved lamp life. Timers fit either externally to, or internally within the containment vessel, can operate in hazardous and non-hazardous conditions, within a wide temperature range, and at a variety of voltages.

Heating Jacket

The heating jacket is an additional accessory for standard (view through) sight flow indicators. Steam from the heating jacket prevents cool spots in the process line while allowing observation and preserving a clear view of the manufacturing process.

Use of the wide variety of available sight glass accessories can significantly improve the drug manufacture process.