Process Observation Solutions: LJ Star Design Capabilities Enable Sight Glass Window Customization

The best process observation window might not be in a catalogue or sitting on a warehouse shelf. It might exist as an idealistic drawing on the back of a napkin. Or the opposite of ideal might be expressed in an email, as mounting frustration related to sight glass windows that repeatedly fail, bringing production to a halt and necessitating continual replacement orders.

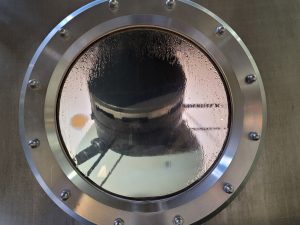

The team at LJ Star can help guide the process of designing and fabricating custom orders for sight glass windows to make it easy for you to turn idealistic concepts into viable reality and end your frustrations. We can help analyze your process observation parameters and work collaboratively on a new design that best fits the needs of your operation. Getting started, it helps to understand some of the factors that demand a custom approach and which options can get the sight glass observation port from a sketch into operation.

Primary Factors Behind Customization Requests

Process observation customization requests for sight glass windows normally fall into one of three buckets: materials, sizing, or temperature/pressure requests that an off-the-shelf product cannot accommodate.

One of the most common causes of sight glass failure is chemical corrosion. Keep in mind that under the right conditions, even harmless fluids can turn corrosive. For example, under pressure combined with higher temperatures (450 degrees Kelvin), water will degrade glass.

Caustic substances therefore impact sight glass selection. Sodium hydroxide, hot concentrated alkaline solutions, phosphoric acid, or fluorine for example, require specialized transparent materials with greater chemical/abrasion resistance than borosilicate glass.

Sight Glass Window Features Available for Customization

Almost half of custom requests involve a new project, with the other half seeking to fix a problem caused by a catalog or off-the-shelf sight glass that did not meet expectations. As one example, a customer in the chemical industry working with caustic fluids was forced to replace its sight glass windows every three to six months.

It approached LJ Star for a more resilient solution than it was experiencing with its current supplier. The engineering team at LJ Star developed a sapphire glass alternative for their existing window material to increase the window’s service lifetime in a highly caustic environment.

During the process, the team at LJ Star demonstrated how the sapphire glass would alleviate the chemical attack and showed there was a backup safety plan in place. While the initial expectation was for a two-year service life, the company realized five-plus years’ worth of service.

Other features available for customization in addition to the transparent material that allows port observation would include:

- Port sizes

- Selection of metals/alloys for the outer ring or collar

- Bolt and gasket material selection or placement

- Specialized mounting fixtures for lights

- Hinges

- Protective shields over the glass, such as mica or Teflon film

- Accessories such as:

- Wipers, to aid in interior visibility

- Spray rings/nozzles

- Heating jackets

- Interior lighting fixtures, including timers

- Proximity switches

‘Glass’ Options and Features

METAGLAS® sight glass windows typically rely on borosilicate glass. It has a lower coefficient of thermal expansion than soda-lime glass of any type, which makes borosilicate highly resistant to thermal shock. It also meets USP Type 1 standards for parenteral products such as injectable drugs and will not leach into the process media—a risk with soda lime glass. The vast majority of applications involving high temperature/high pressure (>95%) can rely on the performance of METAGLAS® for sight glass ports.

However, extreme conditions call for custom materials. Tempered borosilicate glass can withstand temperatures up to 280° C (536° F). Higher temperatures, such as those encountered in high temperature steam applications, would call for a fused quartz or sapphire glass.

Sapphire glass technically is not glass at all, but a ceramic made of pure aluminum oxide. It is formed when aluminum oxide, ground into a powder, is heated at extremely high temperatures and formed into transparent sheets of the desired thickness. It is part of a class of materials known as corundum, characterized by hardness, durability and resistance to corrosion and abrasion. On the Mohs scale for hardness for example, diamonds score a ten, while members of the corundum group score a nine.

Sapphire glass possesses:

- High thermal stability

- High impact/abrasion resistance

- High abrasion resistance, to retain observation clarity

- Excellent mechanical wear resistance

- Excellent serviceability over a broad temperature range

- Chemically inert up to (2000° F).

Process, Prototypes and Verification

Engineers and suppliers are pulled into the customization process observation solutions as needed. The process begins with an exploration of the process parameters, such as time, temperature, abrasiveness, pressure, etc. If it is a replacement, an examination of what caused previous sight glass window failure will occur.

The total process from design to finished product can take four to eight months, depending on a customer’s internal quality control procedures.

After the material selection and design, if necessary, LJ Star can hire a third-party specialist to review the materials and expectations of the sight glass port based on process parameters for size, temperature, and pressure, etc.

LJ Star can manufacture a single or small set of prototypes for clients upon request.

Whatever portion of your process requires observation, sight glass windows should be able to provide:

- Visual verification of a production stage

- Level checks

- Media or fluid inspection for desired (or undesirable) changes in color, consistency, or composition

- Liquid level observation

- Evaluate equipment conditions

- Verify flow (through piping)

Most sight glass suppliers only provide catalog options. Companies can rely on LJ Star for custom process observation solutions when off-the-shelf cannot meet off-the-charts requirements. Our team will work through the application specifications and match up the components to fabricate a sight glass port that delivers the reliability, longevity and safety required while allowing for unobscured process observation. Find the help you need. Call us today.