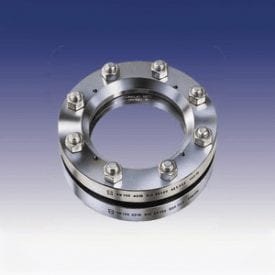

Solutions for Food & Beverage

The right process observation solution can increase your production efficiency, ensure sanitary compliance and help you deliver a better product. Speak with the industry experts at LJ Star today, so you can see a better tomorrow.