Any plant operator can tell you that an innocent-looking set of pipes can conceal nasty secrets, some as petrifying as the monster hiding in the plumbing in a Harry Potter movie. A sight flow indicator is a good way to discover what’s lurking within.

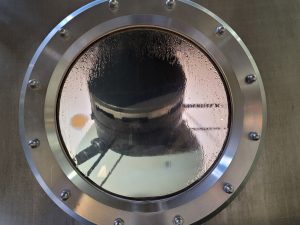

These simple, low-cost devices provide a visual means of verifying liquid flow for direction and approximate rate, and also to observe the color and clarity of process fluids. The body of a sight flow indicator is equipped with one or more viewing windows, usually with gaskets, and a way to mount the indicator to the pipeline, such as a flanged, threaded, or sanitary clamp fitting. They are available to fit standard pipe sizes ranging from ¼-inch to 16 inches and carry ANSI pressure ratings.

Sight flow indicators are applicable to almost every phase of process media movement, whether the media is liquid, gas or powder. Here are some examples:

- In the processing of bulk solids such as plastic resins, inorganic powders, and food products, sight flow indicators make it possible to observe blending and confirm the free flow of materials.

- Sight flow indicators allow personnel to inspect pipelines for residue, scale, and foreign matter, especially during cleaning routines.

- For pipes carrying steam, sight flow indicators can be used to alert personnel to the presence of condensate so they can take steps to eliminate it.

- A chemical processing system often involves a number of pipelines used to move liquid product though cooling lines, filters, and transfer/pumping lines. Sight flow indicators let operators observe line conditions for signs of clogging or blinding filters.

- In discrete manufacturing, machines depend on adequate lubrication to operate smoothly. Equipment with sight flow indicators allows maintenance personnel to detect the absence of oil and to inspect the color of the oil, which may indicate it needs to be changed.

The first step in choosing the right sight flow indicator for a specific application is to define the process to be observed, including temperature, pressure, the physical characteristics of the process media, the direction of flow, and the process’s sterile requirements (if any). To learn more about what’s involved, download a free copy of L.J. Star’s Sight Flow Indicators Handbook: Selection and Application of Sight Flow Indicators in Process Applications.