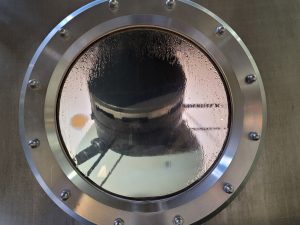

Is your sight glass tough enough to handle “The Big Six” challenges?

Sight glass failures can be extremely dangerous. A sight glass that fails catastrophically has the potential for severe operator injury or death, as well as costly downtime and product losses. Even minor cracks, scratches or abrasions can create weakness within the sight glass, which will most likely lead to failure. In normal use, sight glasses are regularly subjected to forces involving extremes of pressure, temperature, thermal shock, caustics, abrasion, or impact.

Our “6 Tips for Critical Sight Glass Applications” white paper provides expert advice on how to select a sight glass designed to withstand these challenges:

- Temperature: Depending upon the temperature range, certain glass types will perform better than others. At less than 300°F, standard Soda Lime glass may be used. For temperatures up to 500°F, borosilicate glass may be used. At higher temperatures such as in high temperature steam applications, we recommend quartz or sapphire glass.

- Thermal Shock: Some glass types are particularly vulnerable to cracking as a result of rapid temperature change, due to their low toughness, low thermal conductivity, and high thermal expansion coefficients.

- Corrosion: Materials in process media like hydrofluoric acid, hot phosphoric acid and hot alkalis can etch the glass, producing a cloudy view with weakened integrity that requires the sight glass to be replaced.

- Abrasion: Fluids that contain granular particles in suspension, or with particles carried in process gasses can abrade and erode a site glass, limiting visibility and affecting its strength.

- Pressure: The glass materials selected, the unsupported diameter, and the glass thickness all play a role in determining the pressure capabilities of a sight glass assembly. Fused sight glass windows offer high pressure ratings and high safety margins. The strongest fused sight glasses are made from duplex stainless steel and borosilicate glass; this combination creates the highest compression.

- Impact: Objects that strike the sight glass are seldom sufficient to cause immediate failure, but they can create scratches or gouges that provide a point for tensional force to concentrate. Scratched sight glasses should be replaced immediately.

For details on how to take on these challenges, download our free copy of the “6 Tips for Critical Sight Glass Applications” white paper.