Sight glasses (also called sight windows or viewports) are critical for visual inspection inside vessels, pipes, and tanks—but they also represent a potential safety vulnerability if mis-specified, improperly installed, or poorly maintained. There are a variety of critical safety tips and best practices to follow, based on LJ Star’s many years of selling METAGLAS®, the #1 sight glass in the world, along with working with processing facilities in some of the harshest environments.

To highlight these tips, LJ Star has published a new safety video that outlines these procedures to follow.

Key Safety Tips

Standard sight glass safety guidance includes:

- Always depressurize and cool the system before working on or around the sight glass. Never loosen or disassemble under pressure.

- Use personal protective equipment (PPE) (especially eye protection and face shields) when servicing or cleaning a sight glass.

- Avoid over-torquing flanges or clamps or nuts—excessive mechanical stress can cause microcracks or weaken the glass.

- Inspect before re-pressurizing. Check for signs of damage (scratches, chips, hairline cracks) before bringing the system back up.

- Guard the glass with protective screens or protective cover to contain fragments in the event of breakage, directing them back toward the vessel, not outwards into work areas.

These basic precautions help reduce the risk of sudden glass failure or injury during maintenance and operation.

More Best Practices and Technical Guidance from LJ Star

LJ Star reinforces and expands on these principles with a wide variety of tutorial materials, including:

-

Choose the right glass and design spec

LJ Star emphasizes six critical parameters in its “Six Tips to Safety” white paper: temperature tolerance, thermal shock resistance, pressure rating, chemical/corrosion resistance, impact resistance, and abrasion resistance.

In fact, its METAGLAS fused sight glass is designed to incorporate compressive stress (by fusing glass into a metal ring) so that in service the glass is under compression, which dramatically reduces tensile stresses that lead to cracking. You can read why so many processors specify METAGLAS here.

-

Standards and documentation

LJ Star insists on third-party compliance with standards (e.g. DIN 7079, DIN 7080, and USP Type I). In addition, because it’s so important to ensure transparency with the materials we use, LJ Star maintains an on-demand database called MetalTrace® where customers can identify specifically what glass and metals materials are used in every sight glass we produce. LJ Star is the only sight glass manufacturer to provide this level of materials traceability.

-

Installation/maintenance guidelines

A wide variety of installation, maintenance and inspection guidelines are also available in our sight glass handbook, which you can obtain here.

- Correct alignment: misalignment or angular stress can introduce bending in the glass, risking fracture.

- Proper gasket and seal selection: the gasket must be compatible with process fluid and temperature.

- Avoid over-tightening clamps or bolts. Mechanical stresses from overtightening are a common source of failure.

- Use protective shielding or guard installations. LJ Star’s designs often include guard provisions in line with safety best practices.

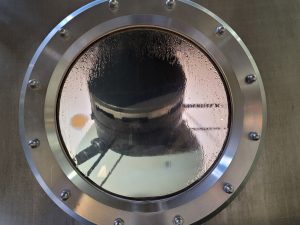

- Perform regular visual inspections for scratches, etches, or clouding. Even small defects can be stress concentrations.

- Replace sight glasses on a scheduled basis to relieve long-term sealing stress. Over time gasket clamping can fatigue the glass.

- Clean carefully. Use proper brushes or remove the glass rather than risk contact damage.

- Maintain a guard or cage around the glass to prevent accidental mechanical damage—e.g. from tools or projectiles.

-

Education & procedural controls

Operators and maintenance personnel should be trained on the limitations of sight glasses, inspection checklists, and safe work procedures. Clear procedural steps (e.g. depressurize → check → replace → re-pressurize) help avoid human error.

Finally, tank and vessel designs should incorporate features that mitigate risk: pressure relief, redundant observation options (e.g. cameras), and containment in case of glass burst.

Watch our sight glass safety video, and visit our Resource Center for access to all of our sight glass white papers, handbooks and videos. Or contact our tech support teams for questions about your specific application.