Why METAGLAS® Is Considered the Safest Sight Glass in the World

Since it was developed in the 1970s, METAGLAS® has been known as the safest sight glass in the world. A number of chemical and manufacturing companies collaborated to create METAGLAS, and to establish the standard with which it complies and by which all other sight glass is measured, a standard now called DIN7079.

METAGLAS was created to improve safety conditions within plants that handled corrosive chemicals, chemicals worked at high temperatures and those worked under high pressures. The safety concerns became serious enough that competing companies joined forces to create METAGLAS.

How It Is Made

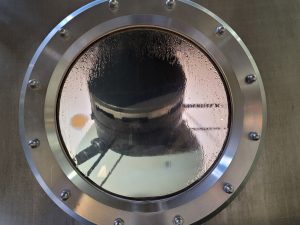

METAGLAS products are made by melting glass inside a circular metal frame, thereby fusing the glass and metal. As the glass cools and solidifies, the difference in the linear coefficient of thermal expansion between glass and metal creates a uniform compressive stress throughout the glass. The glass prevents the metal ring from shrinking back to its theoretical size upon cooling and it remains in tension.

The high degree of mechanically induced compressive stress caused by this physical relationship between the metal and glass makes METAGLAS the strongest and most secure glass for sight window or visual flow indicator applications.

Even at the most extreme temperatures (as high as 536° F) or in overpressure situations, sudden, total failure – that involves explosive shattering of the glass – has never been reported.

The Variety of METAGLAS

METAGLAS sight windows are available in numerous products including visual flow indicators, sight glass windows, sanitary fittings and gauge glass. These glass elements provide a level of safety and duration of service that goes well beyond that provided by conventional tempered glass or plastic.

Premium Borosilicate Glass

LJ Star’s METAGLAS uses a premium borosilicate glass that provides excellent transparency in a range of thicknesses and across the visible spectrum from near ultraviolet (UV) through much of the infrared (IR) spectrum, according to results published on the LJ Star website. (See Figure 1.)

Beware of suppliers who offer a low-quality product. Soda-lime glass is often used as an inferior substitute for borosilicate glass. Request third-party documentation of the glass composition in order to confirm that you are purchasing genuine borosilicate.

The Strongest Sight Glass Available

In addition to offering excellent transparency, METAGLAS mechanically prestressed windows are considered the strongest, most secure sight glass elements available. (See Figure 2.)

Significantly Resistant to Chemical Corrosion

Borosilicate glass has been found to be much more resistant to chemical degradation or disintegration when compared with soda lime glass. (See Figure 3.) The chemical degradation or disintegration of soda lime glass occurs much more quickly beginning both at slightly acidic conditions (pH=6), and at alkaline conditions (pH=10). As shown in the Figure, the degradation of soda lime glass is 10 times greater than that of borosilicate glass. This considerable divergence in resistance properties begins at 134°C, according to a study reported on the LJ Star website. (Move to previous page, above chart.)

Conclusion

METAGLAS was created during a period of industry-wide collaboration where competitor companies worked together to devise a product that would make their manufacturing facilities safer. LJ Star has expanded the use of METAGLAS to encompass nearly every industrial situation in which visual observation is required where dangerous chemicals are used, or used at high temperatures or high pressures. The use of METAGLAS has significantly reduced the risks to workers in and around these plants.