Selecting the right sanitary safety relief valve is crucial, but it’s only the beginning. Even the best-engineered valve can fail if it isn’t installed, operated, and maintained correctly. Here’s a comprehensive guide to ensuring reliable, hygienic performance throughout the valve’s life.

When designing systems for sanitary applications, it’s vital to understand why sanitary safety relief valves differ significantly from their industrial counterparts. You can’t just substitute a robust industrial valve and call it a day—doing so risks contamination, compliance violations or breakdowns during critical moments.

How to Select the Right Sanitary Safety Relief Valve for Your Manufacturing Process

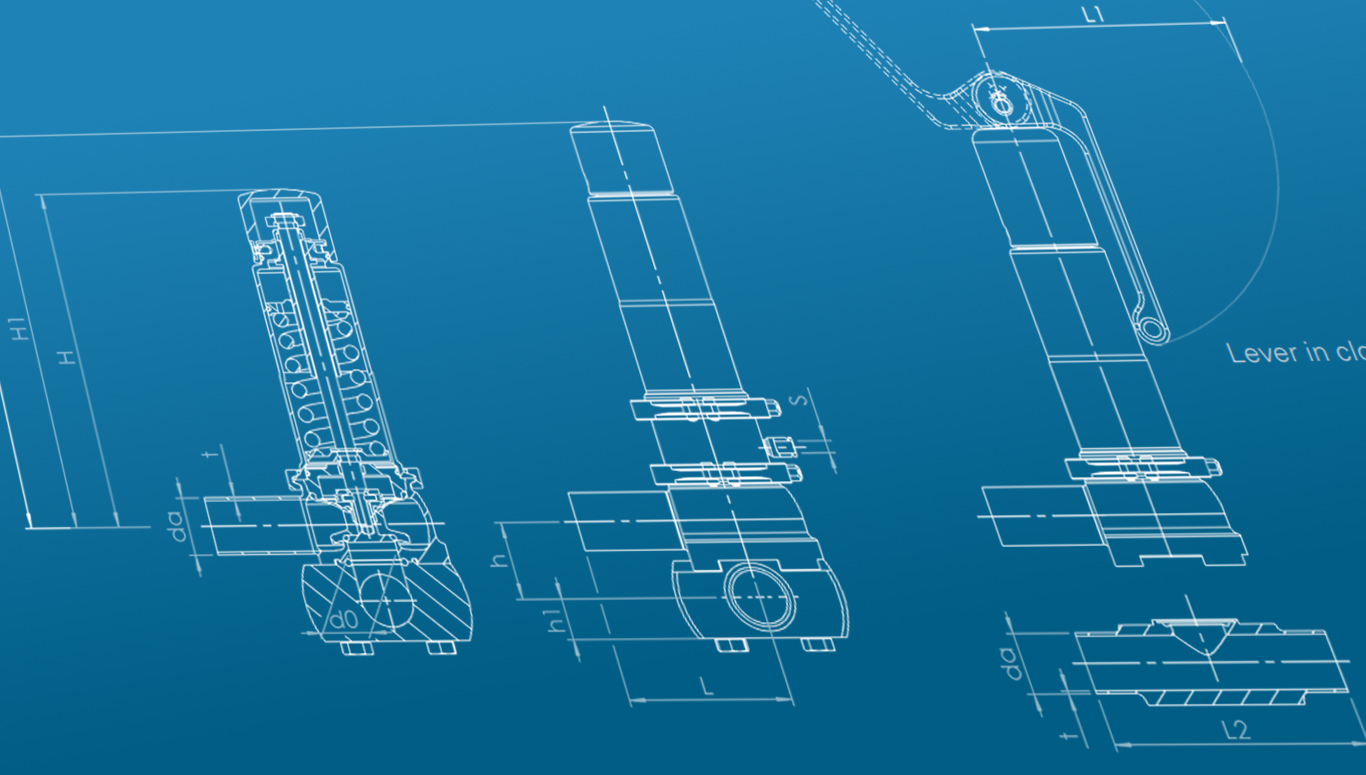

Selecting the proper safety relief valve for sanitary processing equipment is a fundamental engineering decision that impacts plant safety, product integrity and operational compliance. While the general goal is to protect against overpressure, the design details of sanitary applications—like food, beverage, dairy, or biotech—add unique layers of complexity to the decision-making process.