Process plant engineers consistently prioritize two critical goals when it comes to sight glass management: preventing unexpected downtime and minimizing safety risks from potential system failure. Sight glasses may seem like simple components; however, their failure can halt production for extended periods and create significant safety hazards.

While there are various options for sight glass materials, one type of sight glass, METAGLAS®, offers a unique advantage that is not well known—METAGLAS sight glass observation components are uniquely reusable. This feature not only extends service life but can also help reduce plant downtime while enhancing operational safety.

Are you looking for better insight into your processes? Or to prevent waste? Improve safety? Enhance product quality? A sight glass observation port can check all these boxes and more. However, there are boxes equally as important to check off to select the right sight-glass window for your tanks and process vessels.

The adage about a picture being worth a thousand words translates more pragmatically into worth measured in dollars in industries that requires or benefit from process observation and analysis. A ruined process or a wasted batch costs companies money and wastes time, while observation can help prevent such occurrences.

A sight glass observation port provides a view into the interior of the process vessel or tank. It supplies numerous benefits to monitor the vessel’s contents and processes, such as ensuring chemical reactions occur at the appropriate time, that liquid or fluid levels are maintained or that cleaning processes are conducted properly, as a few examples.

Presenting the pros and cons for biopharmaceutical processing

Single use technologies (SUTs) entered the biopharmaceutical industry in the 1990s, and processors were quick to take advantage of this alternative to traditional stainless-steel tanks /equipment for production lines. Single use production runs a process through equipment one-time using high-performance polymers for disposable components that have been sterilized using gamma irradiation. Over time, companies have sifted through the pros and cons of both types of technologies, SUTs and stainless steel, to determine the best options for business operations.

Process Observation Solutions: LJ Star Design Capabilities Enable Sight Glass Window Customization

The best process observation window might not be in a catalogue or sitting on a warehouse shelf. It might exist as an idealistic drawing on the back of a napkin. Or the opposite of ideal might be expressed in an email, as mounting frustration related to sight glass windows that repeatedly fail, bringing production to a halt and necessitating continual replacement orders.

The team at LJ Star can help guide the process of designing and fabricating custom orders for sight glass windows to make it easy for you to turn idealistic concepts into viable reality and end your frustrations. We can help analyze your process observation parameters and work collaboratively on a new design that best fits the needs of your operation. Getting started, it helps to understand some of the factors that demand a custom approach and which options can get the sight glass observation port from a sketch into operation.

A recent article in Food Processing highlighted the importance of a master sanitation schedules. Essentially this schedule serves as a “back-up” to your daily maintenance procedures but involves the periodic cleaning and care for equipment and infrastructure inaccessible to daily cleaning activities.

The article covers two essential parts of the master sanitation schedule – the creation of the schedule and validating the procedures outlined in the schedule.

Schedule Creation

The starting point of creating the schedule, according to the article, is identifying where in your process you have contamination risk. Where are parts that could become a risk, either from poor design, material composition, process requirements, or other factors? Once identified, these non-compliance risks should be analyzed, and a set of cleaning requirements determined and added to the master sanitation schedule.

Schedule Validation

The practical application of the schedule requires validation. The article lays out a method that involves disassembly to reach the parts and visual inspection prior to taking samples both before and after the outlined cleaning. In this way, possible contaminants can be identified, and the cleaning procedure’s effectiveness and frequency are ensured.

Sight Glasses – A Window Into Your Master Sanitation Schedule

It stands to reason that the more parts that are a contamination risk and not readily accessible, the longer your master sanitation schedule, and the more production time lost to accessing and cleaning those parts. However, using accessible and hygienically designed equipment can reduce the number of items that could pose a contamination risk and reduce the time and effort needed to address them in the master sanitation schedule.

LJ Star has several products that fit those criteria.

Our sanitary sight glasses let you see more parts of your process, eliminating unknown corners that could become a concern while offering improved hygienic operation. Properly installed sanitary fittings make disassembly easier to perform and are less likely to add to contamination risks. In addition, LJ Star offers flow indicators, sight windows, bubble traps, and other sanitary products designed to meet various hygienic standards, along with the documentation and traceability to ensure they are, when properly maintained, the products that match your precise specifications.

The LJ Star Resource Center has many tools to help you and your company ensure sanitary standards.

While inherently resistant to corrosion, sight glasses can begin to corrode under the right circumstances, particularly if the wrong material is spec’d for the application. If a sight glass happens to corrode, it becomes increasingly vulnerable to sight glass failure. When glass fails, it is often sudden and catastrophic, damaging your system, putting workers at risk, and causing unplanned downtime. That’s why it’s important to understand the dangers of sight glass corrosion and failure so that you can adequately prepare for them… and avoid a costly disaster.

The purpose of a sight glass is to allow plant managers and engineers to look inside of their systems without disrupting the environment within. Often referred to as viewing glasses, they offer you a way to see the levels of liquids or gases that are traveling through a critical point of your design, monitor pressure changes, and virtually anything else that sight glass windows could allow you to do. With their widespread use, sight glasses have become critical to operations such as steam pipelines, chemical processing, pharmaceutical processing, and food processing.

The purpose of a sight glass is to allow plant managers and engineers to look inside of their systems without disrupting the environment within. Often referred to as viewing glasses, they offer you a way to see the levels of liquids or gases that are traveling through a critical point of your design, monitor pressure changes, and virtually anything else that sight glass windows could allow you to do. With their widespread use, sight glasses have become critical to operations such as steam pipelines, chemical processing, pharmaceutical processing, and food processing.

Keeping an Eye on Sight Glass Safety

If improperly specified, installed or maintained, sight glasses can be the weakest link in a processing system because they can limit observation capabilities, require frequent maintenance or replacement, or make it difficult to illuminate the vessel in which they’re installed.

Why METAGLAS® Is Considered the Safest Sight Glass in the World

Since it was developed in the 1970s, METAGLAS® has been known as the safest sight glass in the world. A number of chemical and manufacturing companies collaborated to create METAGLAS, and to establish the standard with which it complies and by which all other sight glass is measured, a standard now called DIN7079.

Using sight glasses is essential in the production of pharmaceuticals, as is maintaining the functionality and cleanliness of those sight glasses. The good news is that a wide variety of sight glass accessories are available to assist pharmaceutical manufacturing personnel in the production of pure, high-quality product in every batch.

Using sight glasses is essential in the production of pharmaceuticals, as is maintaining the functionality and cleanliness of those sight glasses. The good news is that a wide variety of sight glass accessories are available to assist pharmaceutical manufacturing personnel in the production of pure, high-quality product in every batch.

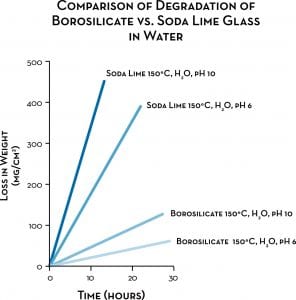

As hot water passes through ground coffee beans, it extracts flavors, colors, and stimulants that make mornings more livable for many of us. When it comes to pharmaceutical processing, however, extraction can be a bad thing, as leaching from process system surfaces can extract unwanted elemental impurities.

What is a sight glass? Definitions for common sight glass terms.

A sight glass, which can also be referred to as a sight port window or a sight window, is an observation window that allows you to look at fluid stored under high temperatures, extreme pressures, and other extreme environmental conditions. They are typically made of robust glass substrates that are used to analyze conditions in industrial equipment, chemical reactors, and more.

Sight glasses are used in industries ranging from refineries to craft breweries. They allow you to look inside equipment without having to worry about explosions, corrosion, or other types of damage. Perhaps because of their widely-varied applications, sight glasses are called by different names. Broadly speaking, a sight glass is any kind of window on a process vessel

A sight glass seems pretty straightforward: a fitting with a window installed on the top or side of a vessel that you can look through and see what’s going on. Simple, right?

A sight glass seems pretty straightforward: a fitting with a window installed on the top or side of a vessel that you can look through and see what’s going on. Simple, right?

Not so fast. There is a wrong way to do anything, and choosing the wrong type of glass for a sight glass can have bad

I have a tank and need a sight glass. What are my options? Although this may seem like an innocuous question… many factors come into play. While the choice is clear for some customers, there are many more for whom this choice is anything but clear.

I have a tank and need a sight glass. What are my options? Although this may seem like an innocuous question… many factors come into play. While the choice is clear for some customers, there are many more for whom this choice is anything but clear.

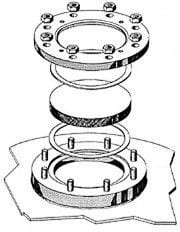

Sight glasses allow you to safely observe processes inside your tanks, vessels, pipes, and reactors. It is a window that allows operators to inspect the process media, observe reactions, observe the functioning of mixing equipment, verify the presence or absence of media, see liquid level, etc. It consists of metal, glass, and gasket components. In order to ensure optimal performance, a variety of factors need to be considered. Here are 5 critical things to consider when specifying a sight glass for your process.

Sight Glass Maintenance Tips from L.J. Star Incorporated