How to See What Others Miss: Sizing Effective Process Lighting for Industrial Facilities

Posted by John GiordanoPicture this scenario: A major brewery was losing thousands of dollars per batch because its process consistently resulted in beer with a more bitter flavor profile than intended. After extensive troubleshooting, the brewery discovered the root cause wasn’t its recipe or fermentation process—instead, it was something they couldn’t see. Literally.

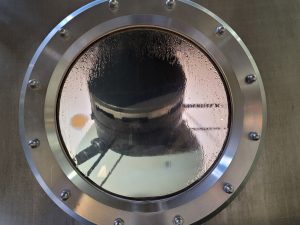

Inadequate lighting within the process vessels prevented operators from properly observing the washdown cycle between batches. This washdown cycle consistently left residue that contaminated subsequent brews. Once the brewery installed proper process lighting, the team could see that the spray nozzles within the process tanks were not positioned correctly and therefore not completing the cleaning process. Truly shining a light into the darkness, proper lighting in the right strength and in the correct place helped correct a problem that had been hidden in the shadows.

This story illustrates a critical truth in industrial processing: if you can’t see it, you can’t control or optimize it. While sight glasses provide windows into your process vessels, ambient lighting rarely delivers the illumination needed for effective observation. Whether you’re verifying complete washdown cycles, monitoring product consistency, detecting foam levels or ensuring proper mixing, specialized process lighting supplies the illumination that transforms your ability to maintain quality control, avoid waste and improve operational efficiency.

The LED Revolution in Process Lighting

The process lighting landscape has undergone a dramatic transformation, with LED technology now dominating process applications. This shift represents more than just following commercial lighting trends—it addresses specific challenges that processing facilities face daily.

LED process lights offer compelling advantages over previous-generation halogen and metal halide technologies. Most significantly, LED lights generate minimal heat output, with only 5% of energy lost to heat compared to 70-80% in legacy halogen systems. This “cold light” characteristic proves crucial for temperature-sensitive processes where traditional lighting could compromise product integrity or process conditions.

The durability factor cannot be overstated. LED lights resist shock and vibration—common challenges in many processing environments—while delivering consistent performance for five years or more. Unlike prior halogen systems with fragile filaments that often failed under stress, LED units maintain reliable operation even in high-vibration applications.

Critical Factors for Proper Sizing

Selecting appropriate process lighting requires understanding multiple variables that impact illumination effectiveness. Simply knowing your vessel’s volume provides insufficient information for proper sizing. Engineers must consider several key factors:

- Vessel characteristics: Overall dimensions, height and interior surface materials significantly impact lighting requirements

- Product properties: Dark materials absorb more light requiring higher illumination, while lighter materials reflect light and need less; vessel interior surfaces also matter – stainless steel vessels provide high reflectivity while glass-lined vessels typically absorb more light

- Viewing requirements: Determine whether you need to observe the full vessel depth or specific areas

- Distance considerations: Light intensity decreases with distance, so the depth from the light source to the target viewing area affects the required lumen output

Distance calculations prove particularly critical. A 40-foot tall tank might only require observation of the top 5 feet when full, but operators may need to see to the bottom when empty. Each scenario demands different lighting intensities and configurations.

Color temperature selection also matters. Stainless steel vessels perform optimally with higher color temperature lighting, while darker vessel interiors may require different spectral characteristics for maximum visibility.

Mounting and Configuration Options

Process lights always mount externally to sight glasses, never entering the vessel interior. This design principle maintains vessel integrity while protecting lighting equipment from process media. However, mounting configurations vary significantly based on application requirements.

Facilities can choose between separate light and observation ports or combination units. Sanitary connections like tri-clamp systems typically dedicate entire ports to lighting, requiring separate observation points. Bracket-mount systems can retrofit existing sight glass installations, while custom mounting solutions address unique vessel configurations.

For facilities requiring explosion-proof ratings, specialized housings meet Class 1 Division 1 (C1D1) and Division 2 (C1D2) requirements or European ATEX standards. The key difference is the frequency of the hazardous atmosphere, whether constant or intermittent. These applications also must consider temperature class restrictions that limit maximum allowable surface temperatures in hazardous environments.

Advanced Control and Integration Capabilities

Modern LED process lighting systems offer sophisticated control options that integrate seamlessly with existing facility automation. Lights can operate continuously, activate with specific process events, or follow programmed cycles that optimize both visibility and equipment longevity.

Some applications benefit from custom programming. One brewery customer required lights that operated at full power initially, then automatically reduced intensity to prevent heat buildup, with warning signals before shutdown. This customization prevented premature equipment failure while maintaining necessary illumination.

Integration with camera systems enables comprehensive monitoring solutions. Synchronized lighting and video capture provide documented evidence of process conditions, supporting quality assurance protocols and troubleshooting efforts.

Maintenance and Longevity Considerations

LED process lights require minimal maintenance compared to prior technologies. Unlike halogen systems requiring frequent bulb replacement, LED units operate for years without intervention. However, facility managers should recognize LED degradation patterns differ from conventional lighting.

LED lights typically exhibit gradual dimming before failure, providing advance warning, unlike halogen bulbs that simply burned out. This characteristic allows proactive maintenance scheduling, but facilities should maintain backup lighting for continuous monitoring applications.

For critical processes, having spare lights readily available prevents extended downtime. While LED units cannot accept simple bulb changes, manufacturers often offer cost-effective repair and refurbishment services for aging units.

The Business Case for Proper Process Lighting

Investing in appropriate process lighting delivers quantifiable returns through multiple channels. Enhanced visibility prevents product contamination, reduces batch losses and improves cleaning verification. Safety benefits include eliminating dangerous manual inspections that require workers to climb tall vessels or enter confined spaces.

The brewery case study mentioned earlier demonstrates these benefits clearly. Their lighting and camera system investment represented a fraction of the cost compared to continued product losses. The solution provided immediate ROI while establishing long-term quality control capabilities.

Energy efficiency adds another economic advantage. LED systems consume significantly less power than traditional alternatives while delivering superior illumination. Reduced maintenance requirements and extended service life further improve total cost of ownership.

Process lighting represents a foundational investment in operational visibility and control. As facilities continue optimizing efficiency and quality assurance, the ability to clearly observe process conditions becomes increasingly valuable. The technology exists to illuminate what others miss—the question is whether your facility can afford not to see clearly.

Ready to improve your process observation capabilities? Watch our complete webinar for detailed technical specifications and application examples, or visit our website to explore our full range of process lighting solutions designed specifically for industrial environments.