Why Reactive Maintenance is Costing Your Plant Millions—And What to Do About It

Posted by Scott KloetzerIn process manufacturing facilities across the country, a costly pattern repeats itself daily: equipment runs until it fails, alarms sound and maintenance teams scramble to patch things together. This reactive approach might seem like the right way to stretch tight budgets, but this practice is actually bleeding companies dry—and creating dangerous conditions in the process.

Scott Kloetzer, Director of Business Development at LJ Star, has witnessed this scenario countless times during visits to process facilities in a wide variety of industries. In a recent episode of the Processing Pros podcast, sponsored by Processing Magazine, he pulled back the curtain on the current state of maintenance culture in process manufacturing—and the picture isn’t always pretty.

The High Cost of Running to Failure

The majority of the facilities that Kloetzer visits annually are looking to run the facility to failure, but then panic ensues when the equipment fails. This run-to-failure approach creates a domino effect of expensive consequences:

- rushed equipment orders

- expedited freight charges that can skyrocket with next-day air shipping

- overtime labor costs

- extended downtime that can cost five to ten times what preventative maintenance would have required

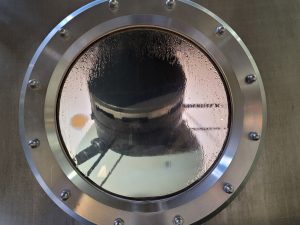

Consider a recent client example: A facility had approximately 20 sight glasses that should have been replaced every couple of years. Budget constraints led them to keep reusing the units, replacing only gaskets while ignoring minor cracking, product film and chemical etching on the glass.

The result? An operator couldn’t clearly see the tank level through the clouded sight glass, leading to an overflow that required extensive cleanup, product disposal and regulatory documentation. The cost of addressing this “minor” issue far exceeded what a staged replacement program would have cost.

The Perfect Storm: Staffing Shortages and Lost Knowledge

The maintenance crisis isn’t just about budgets—it’s about people. A generation of experienced maintenance professionals is retiring, taking 20-30 years of experience and knowledge with them. Meanwhile, companies are waiting until these veterans retire before hiring replacements, eliminating any opportunity for knowledge transfer.

As younger employees take over these facility responsibilities, they have to learn on the job through trial and error, not through structured programs. The result is a handful of “hero” employees who can troubleshoot anything—until they burn out or leave, taking their expertise with them. The “expertise gap” cycle then repeats all over again.

When Technology Becomes a Single Point of Failure

Modern sensors and AI promise predictive maintenance capabilities, but they also introduce new risks when facilities become over-reliant on technology without backup verification systems. In the podcast, Kloetzer referred to a recent refinery fire in California, which experts believe may have been caused by a sensor failure in a high-pressure line.

“There can be major over-reliance on the data being supplied that can lead to issues when refineries don’t have backup mechanisms to track the information,” he explains. This is where visual monitoring technology—often dismissed as old-school—becomes critical in modern facilities.

Visual verification through sight glasses and camera systems provides real-time validation that sensors are functioning correctly. In one case, a customer’s magnetic level gauge was reading 2.5 to 3 inches off from where the glass indicator showed the actual fluid level. Without that secondary visual source, the tank would have been overfilled, causing a costly spill and regulatory headache.

Starting Small: Building a Maintenance Culture Without Breaking the Bank

For manufacturers who believe they can’t afford predictive maintenance systems, Kloetzer offers practical advice for starting small:

- Identify critical assets. Determine which equipment failures would cause the most pain in terms of safety, downtime and quality. Start there.

- Use your senses. Train operators and maintenance teams to use their eyes, ears and hands when walking the plant. Look for leaks, corrosion and anything out of the ordinary. Listen for changes in noise—grinding, knocking, unusual vibrations. Feel equipment for temperature changes and vibrations that signal trouble.

- Empower operators. The disconnect between operators and maintenance teams is a major problem. Operators use equipment daily and are best positioned to notice early warning signs, in a similar fashion a person who drives the same car regularly can easily recognize noises that indicate a problem.

- Create accountability. Assign specific inspection tasks to individuals, build them into schedules and provide clear instructions so coverage continues if someone is out or leaves the company.

- Connect maintenance to financial impact. Help teams understand what downtime actually costs the company. When employees realize they’re saving tens or hundreds of thousands of dollars through simple preventative actions, maintenance becomes a value driver rather than a cost center.

The Leadership Gap

Perhaps the most critical insight from Kloetzer’s experience is this: the problem isn’t an “old school mentality” resisting change among maintenance teams. The problem is leadership that has become hyper-focused on quarterly numbers that sometimes come at the expense of long-term reliability.

As companies cut hours, cut spare part inventories or reduce training budgets, the purchasing department follows a practice of ordering parts and components from the lowest bid, instead of examining what might contribute to the lowest long-term lifecycle costs.

In Kloetzer’s experience, the maintenance professionals he meets in facilities around the country want to move beyond this reactive approach. They recognize jobs run more smoothly with equipment that works reliably and provides durability for long-term service, not the parts that purchasing determines are the cheapest. They want to build consistent preventative maintenance programs. But they need leadership support to make it happen.

Looking Ahead

In a single month before the podcast aired, three major industrial accidents occurred in California, Tennessee and Texas—at least one associated with equipment failure, with the others likely to show similar root causes. These incidents highlight why the prevailing approach to purchase the least expensive components and to run equipment to fail isn’t sustainable.

While AI, machine learning and augmented reality promise to revolutionize maintenance in the coming years, the significant upfront costs mean widespread adoption may still be several years away. In the meantime, facilities can’t afford to wait. Basic preventative maintenance practices—visual inspections, routine checks, operator training and adequate spare parts inventory—can prevent the costly failures that plague reactive maintenance cultures today.

The question isn’t whether companies can afford to invest in proper maintenance. It’s whether they can afford not to. When downtime costs five to ten times what prevention would cost, when lives are at risk and when regulatory consequences loom, the math is clear. It’s time to stop kicking the can down the road and start building a maintenance culture that prevents problems rather than just reacting to them.

Interested in the full story? Listen to the full Processing Pros Podcast here.