While inherently resistant to corrosion, sight glasses can begin to corrode under the right circumstances, particularly if the wrong material is spec’d for the application. If a sight glass happens to corrode, it becomes increasingly vulnerable to sight glass failure. When glass fails, it is often sudden and catastrophic, damaging your system, putting workers at risk, and causing unplanned downtime. That’s why it’s important to understand the dangers of sight glass corrosion and failure so that you can adequately prepare for them… and avoid a costly disaster.

The purpose of a sight glass is to allow plant managers and engineers to look inside of their systems without disrupting the environment within. Often referred to as viewing glasses, they offer you a way to see the levels of liquids or gases that are traveling through a critical point of your design, monitor pressure changes, and virtually anything else that sight glass windows could allow you to do. With their widespread use, sight glasses have become critical to operations such as steam pipelines, chemical processing, pharmaceutical processing, and food processing.

The purpose of a sight glass is to allow plant managers and engineers to look inside of their systems without disrupting the environment within. Often referred to as viewing glasses, they offer you a way to see the levels of liquids or gases that are traveling through a critical point of your design, monitor pressure changes, and virtually anything else that sight glass windows could allow you to do. With their widespread use, sight glasses have become critical to operations such as steam pipelines, chemical processing, pharmaceutical processing, and food processing.

Improperly specified, installed or maintained sight glasses can represent the weakest link in a processing system. The wrong glass or materials used will limit observation, require extra maintenance and replacements, and even fail under pressure with catastrophic results – since glass can fracture at 5 miles/second!

Keeping an Eye on Sight Glass Safety

If improperly specified, installed or maintained, sight glasses can be the weakest link in a processing system because they can limit observation capabilities, require frequent maintenance or replacement, or make it difficult to illuminate the vessel in which they’re installed.

As hot water passes through ground coffee beans, it extracts flavors, colors, and stimulants that make mornings more livable for many of us. When it comes to pharmaceutical processing, however, extraction can be a bad thing, as leaching from process system surfaces can extract unwanted elemental impurities.

What is a sight glass? Definitions for common sight glass terms.

A sight glass, which can also be referred to as a sight port window or a sight window, is an observation window that allows you to look at fluid stored under high temperatures, extreme pressures, and other extreme environmental conditions. They are typically made of robust glass substrates that are used to analyze conditions in industrial equipment, chemical reactors, and more.

Sight glasses are used in industries ranging from refineries to craft breweries. They allow you to look inside equipment without having to worry about explosions, corrosion, or other types of damage. Perhaps because of their widely-varied applications, sight glasses are called by different names. Broadly speaking, a sight glass is any kind of window on a process vessel

I have a tank and need a sight glass. What are my options? Although this may seem like an innocuous question… many factors come into play. While the choice is clear for some customers, there are many more for whom this choice is anything but clear.

I have a tank and need a sight glass. What are my options? Although this may seem like an innocuous question… many factors come into play. While the choice is clear for some customers, there are many more for whom this choice is anything but clear.

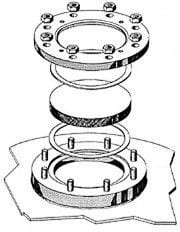

Sight glasses allow you to safely observe processes inside your tanks, vessels, pipes, and reactors. It is a window that allows operators to inspect the process media, observe reactions, observe the functioning of mixing equipment, verify the presence or absence of media, see liquid level, etc. It consists of metal, glass, and gasket components. In order to ensure optimal performance, a variety of factors need to be considered. Here are 5 critical things to consider when specifying a sight glass for your process.

Say green energy, and the first words that spring to most minds are likely either solar power or wind power. But there’s another important player in the alternative energy marketplace─biogas generation.

Biogas is produced when organic matter breaks down in the absence of oxygen. It’s produced by anaerobic digestion by bacteria or fermentation of biodegradable materials such as manure, sewage, municipal waste, or plant material. Like solar and wind power, it’s a renewable energy source. It can be used as a fuel in a variety of applications; when cleaned and compressed, it can power motor vehicles.