- Home

- Products

- Sight Glasses

- Sanitary Sight Glass Windows

-

MetaClamp® Sanitary Sight Glass Window

MetaClamp® Sanitary Sight Glass Window

The strongest, most secure sight glass elements available, METAGLAS® mechanically prestressed windows, are available in a sanitary design for process applications.

Unlike some other sight glasses, METAGLAS® sight glasses meet the USP Type 1 standard for pharmaceutical use.

Described as offering the optics of glass and the strength of steel, these glass elements provide a level of safety, and a useful service life, well beyond that provided by conventional tempered glass or plastic in sanitary service. Even at the most extreme temperatures (as high as 536° F) or in overpressure situations, sudden, total failure – that involving leakage or explosive shattering of the glass – essentially never occurs. Also designed to be mounted in-line as a Sanitary Visual Flow Indicator and to accommadate Lumiglas Luminaires, such as the USL33 or USL35 style.

This L.J. Star product carries Canadian Registration Number (CRN) registration (Ontario currently, in process other Provinces).

Application:

Sanitary MetaClamp®s to fit sanitary clamp connections. The MetaClamp® sight glass can be used as a view port mounted on a ferrule, a “cross” for inline visual flow indication or as a light port. Materials available include 2205 Duplex Stainless Steel, Hastelloy®, Monel® and Inconel®.

Request a Quote

Request a Quote

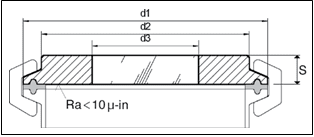

| Standard Tube OD | d1 | d2 | d3 | S | PSIG@450ºF | ||||

| Inch | MM | Inch | MM | Inch | MM | Inch | MM | ||

| 1/2”, 3/4” | 0.98 | 25 | 0.71 | 18 | 0.39 | 10 | 0.39 | 10 | 230 |

| 1”, 1-1/2” | 1.99 | 51 | 1.61 | 41 | 0.98 | 25 | 0.39 | 10 | 230 |

| 2” | 2.52 | 64 | 2.05 | 52 | 1.18 | 30 | 0.39 | 10 | 230 |

| 2-1/2” | 3.05 | 78 | 2.51 | 64 | 1.38 | 35 | 0.47 | 12 | 230 |

| 3” | 3.58 | 91 | 2.99 | 76 | 1.57 | 40 | 0.39 | 10 | 150 |

| 3-1/2” | 4.17 | 106 | 3.54 | 90 | 1.97 | 50 | 0.39 | 10 | 150 |

| 4” | 4.69 | 119 | 3.97 | 101 | 2.17 | 55 | 0.47 | 12 | 150 |

| 6” | 6.57 | 167 | 5.98 | 152 | 2.95 | 75 | 0.63 | 16 | 85 |

| 8” | 8.56 | 218 | 7.80 | 198 | 3.94 | 100 | 0.71 | 18 | 85 |

| 10” | 10.55 | 268 | 9.65 | 245 | 4.72 | 120 | 0.79 | 20 | 85 |

| 12” | 12.56 | 319 | 11.81 | 300 | 5.51 | 140 | 0.87 | 22 | 85 |

Note: Temperature and pressure apply to sightglass only.