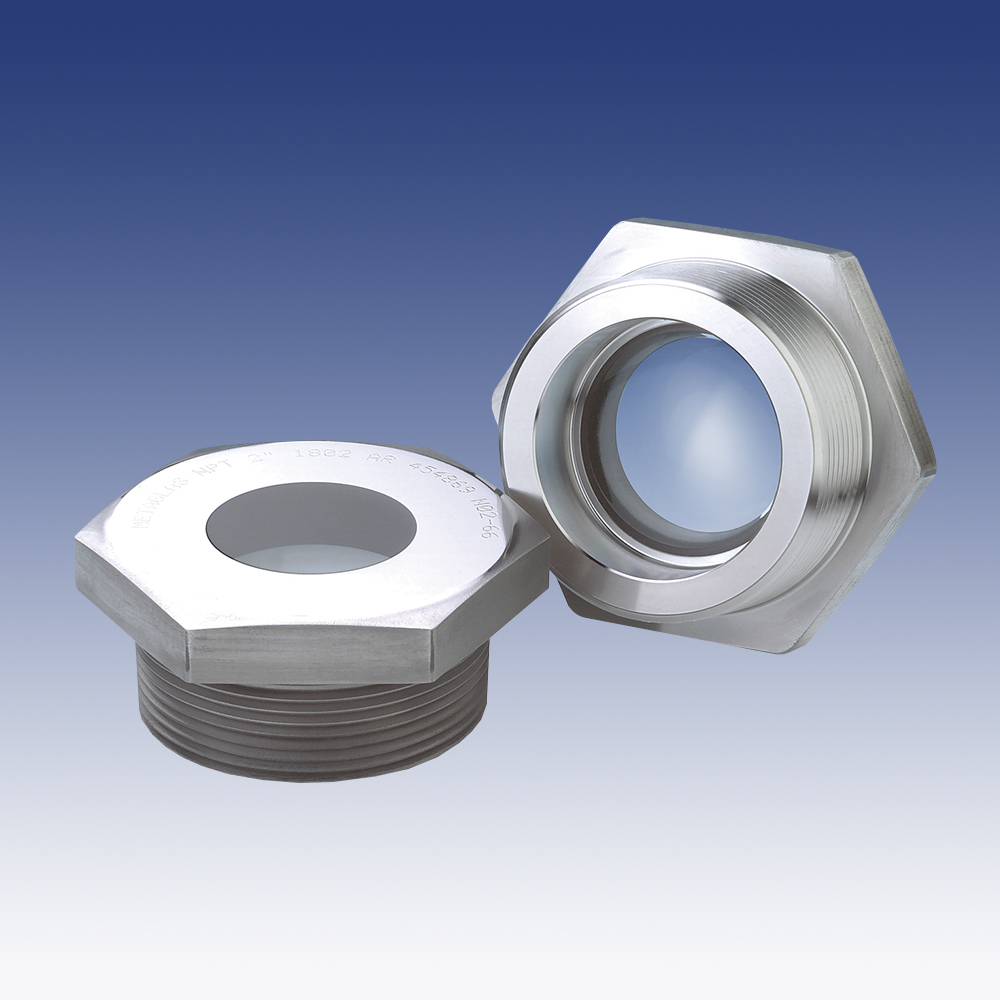

Industrial Threaded Sight Glass Window, METAGLAS®

The strongest, most secure sight glass elements available, METAGLAS® mechanically prestressed windows, are available in a threaded design for process applications. METAGLAS® threaded sight glasses are compliant with the recently revised ASME (founded as the American Society of Mechanical Engineers) standard for electric boilers, Section I PEB-13, Water Gages. The revised ASME standard now allows manufacturers of boilers with a diameter of 16” or smaller to use a bull’s-eye-type fused sight glass window instead of the traditional tubular sight glass for observation of the water level in the boiler.

These sightglass are available in variety of thread type including NPT and metric straight threads. Described as offering the optics of glass and the strength of steel, these glass elements provide a level of safety, and a useful service life, well beyond that provided by conventional tempered glass or plastic in sterile service. Even at the most extreme temperatures (as high as 536° F) or in overpressure situations, sudden, total failure – that involving leakage or explosive shattering of the glass – essentially never occurs.

This L.J. Star product carries Canadian Registration Number (CRN) registration.

Request a Quote

Request a QuoteMETAGLAS® – Threaded Sightglass – NPT-Thread

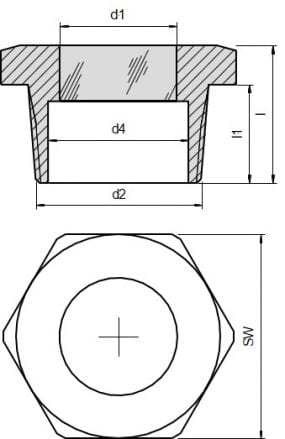

| d2 Thread | SW | d1 | d4 | l | l1 |

| ¼“ NPT | 21 | 9 | 9 | 17 | 11 |

| 3/8“ NPT | 24 | 10 | 12 | 20 | 13 |

| ½“ NPT | 27 | 14 | 16 | 25 | 15 |

| ¾“ NPT | 36 | 18 | 20 | 26 | 16 |

| 1“ NPT | 41 | 21 | 23 | 34 | 19 |

| 1 ¼“ NPT | 50 | 25 | 30 | 30 | 20 |

| 1 ½“ NPT | 55 | 30 | 36 | 36 | 24 |

| 2“ NPT | 70 | 35 | 44 | 40 | 25 |

| 3“ NPT | 100 | 50 | 60 | 55 | 30 |

Advantages:

- Very compact

- High pressure resistance

- Simple assembly

- Long working life

- Ring material: Carbon Steel (1.0570), Stainless Steel (1.4462) Hastelloy

- Glass: Borosilicate to DIN 7080

| Ring materials | Operating temperature |

| Carbon steel 1.0570 | -10°C to +300°C |

| Duplex stainless steel 1.4462 | -30°C to +280°C |

| Hastelloy C22 (2.4602) | -60°C to +300°C |