- Home

- Industries

-

Sight Glass System Aids Biogas Process Efficiencies

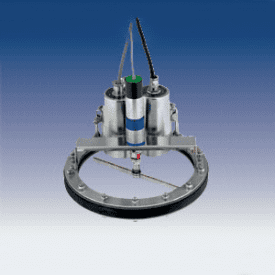

The ability to observe biogas in production is critical to efficient production. LJ Star’s biogas sight glass system is specially made for this application.

Biogas and biofuel production supply their own unique set of challenges for process observation solutions selection, typically involving tremendous heat and pressure, producing a combustible and highly toxic substance. Yet the ability to observe biogas during production is critical to process efficiency. LJ Star solutions, including sight glass systems and components, are designed to handle the pressure and the environment within biogas production facilities to allow for process observation while maintaining stringent safety parameters.

What is biogas?

The prefix “bio” indicates a product that begins with or stems from a living source. Biogas is a renewable, eco-friendly fuel produced when bacteria digest organic matter (or biomass) under anaerobic conditions.

The digester collects gas released during the decomposition of organic matter. A pump transfers the resulting biogas to a station where sulfur content is lowered and methane content optimized, or the usable portion of the biogas.

While biogas production occurs naturally in ruminant animals or within effluent ponds, an engineered container called a digester can leverage this natural process using biomass to create biogas. These biomass or waste materials can stem from:

- Food waste

- Plant matter

- Municipal rubbish or waste

- Animal manure

- Sewage

Biogas, when modified and combusted, can supply heat, electricity, or fuel for transportation. Its vast potential and renewable nature translate into continued, steady industry growth.

Biogas production facilities

Biogas production facilities proliferate around the globe, with most plants found in China and Germany. In addition, the US has operational sites in each of the 50 states, with significant growth predicted through 2030.

Digester tanks typically rely on anaerobic digestion to break down manure and turn it into a gas. These tanks are usually fitted with mixers or augers to ensure the tank’s contents do not develop a crust and trap the gases within the fluids.

Sight glasses aid in observing this process to verify that the mixers or augers perform as desired. This helps with safety measures and optimizes biogas production. Workers also can verify the introduction of new material for the bacteria to digest to maintain biogas production. Other products that aid in sight glass installation and performance in biogas facilities can include:

- Clamps

- Gaskets

- Visual flow indicators

- Explosion-proof LED lights

- Cameras

- Wipers

- Sprayers

Sight glass systems designed for digesters

Tanks can be constructed of concrete or stainless steel. LJ Star supplies different sight glasses designed for each type of digester module. Sight glasses for digester tanks are placed such that operators can observe the mixers and augers and material levels within the tank, with options for remote observation available.

In the case of a concrete digester, the sight window has an innovative expanding gasket that conforms to irregularities in the cement walls and ports used in this style of digester tank, creating a gas-tight seal for safety standards. The model RD300 sight glass window also includes three angled mounting brackets to accommodate the depth of the container wall. The typical viewing area diameter is 220 mm, with an outer ring diameter of 295 mm. Metal components are comprised of stainless steel.

For either concrete or stainless-steel digesters, explosion-proof LED lighting mounted on the sight glass improves illumination. An optional automatic wiper and sprayer help clear materials from the glass interior to ensure clear viewing. Operators can direct the spray as needed. Many companies also select the optional explosion-proof camera to enable remote viewing of the tank’s interior.

LJ Star has installed its sight glass windows on biogas digesters in countries around the globe. Protect worker safety and property and obtain a clear sight of digester processes for greater efficiencies with a reliable and proven sight glass window system from LJ Star.

Are you looking for quality tank components to go along with your process observation solution? Then, visit our sister company Tank Components Incorporated (TCI).