In process industries ranging from industrial, chemical, food/beverage or pharmaceuticals, it’s essential that products are processed in the safest environment possible in order to

comply with a wide variety of regulations. Lighting plays a critical role to safety, of course. In order to see critical processes inside your tanks and vessels, you need the most reliable lighting available. And reliability certainly begins with availability – if you can’t find new halogen bulbs to replace your existing halogens, it’s lights out for your process.

One of the best sight glass lights just got even better. The LJ Star LumiStar®1000, the world’s brightest compact sight glass luminaire, is now Intertek ETL approved and conforms to UL 2108; in Canada it conforms to CSA C22.2 #250.0.

What is the ETL Listed Mark?

Intertek ETL certifications serve as the benchmark for safety and performance in today’s processing equipment. The ETL Listed Mark indicates that a product has

Beer is one of the oldest and the most largely consumed alcoholic beverages in the world. This all-time favorite brew has been a staple at sporting events, social gatherings, and family barbecues for generations. During the past few years, craft beers have created quite a buzz among younger consumers seeking a more unique palette than their parents’ traditional beer. Craft breweries have experienced unprecedented growth by bringing an almost endless variety of beer styles to the market. In fact, the overall global beer market is expected to reach $685 billion by 2025.

For pharmaceutical manufacturers, maintaining the cleanliness of their facilities, especially their stainless-steel process vessels, is Job #1. A UV light for your sight glass can help, as UV light can be used to inspect and verify SIP and CIP procedures have done an adequate job.

Vessels must be cleaned and sterilized thoroughly between each product batch. This is important to prevent contamination from previous batches or residual cleaning agents from adulterating the product. Depending on the type of drug being produced, an inadequately cleaned vessel could potentially force the facility to quality reject millions of dollars’ worth of compromised product.

Like other critical components of getting the perfect brew, conical fermenters need to be closely observed. Fermentation is part art, which means you need to involve your senses: seeing, smelling, tasting. It’s also part science, which means that you need a way to confirm that each stage of the process is going according to plan: that the cleaning solution is fully rinsed, that there is no cross batch contamination, etc. In short, you need a sight glass window on your vessel, and a light to illuminate its interior.

Conical fermenter sight glass lights come in various types and configurations. In my post today I’ll review some of your options, so you can choose the optimal light for your situation. By the way, although I’m focusing on fermenters, which may be conical or straight, the same advice will apply to any brewing equipment vessel, including mash lauter tuns, finishing tanks, and the like.

Conical fermenter sight glass lights come in various types and configurations. In my post today I’ll review some of your options, so you can choose the optimal light for your situation. By the way, although I’m focusing on fermenters, which may be conical or straight, the same advice will apply to any brewing equipment vessel, including mash lauter tuns, finishing tanks, and the like.[vc_row][vc_column][vc_column_text]Food and Beverage ApplicationExperts in the $738 billion food and beverage manufacturing industry know that, for consumers, taste begins with the eyes. This is especially true with beverages, for whom hue, clarity, cloudiness, transparency, opacity and foam are very tightly controlled. Such the domain of the processing engineer, who depends on the sight glass and associated lighting to observe the process media.

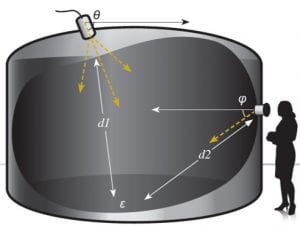

How to Size a Sight Glass Light for a Process Vessel?

Ah, the world of lighting used to be so simple. When you needed to illuminate the interior of a process vessel or tank, you selected a halogen light by its watts. Typically you used a 50 watt light because that’s what the manufacturers commonly offered. If that wasn’t bright enough, then you used a 100 watt light. It got hot, but you didn’t have much choice. The decision for your sight glass light was simple.

Ready to roll…. The time and effort deciding where and when to show has been a challenge for some time. Making the right choices to promote oneself and stay on top of industry trends, demands and forecasting the needs of customers is critical in any business. So when an opportunity arises you’d be a fool to pass it by. And this week LJ Star, Inc will be taking advantage of such an opportunity by showing at the American Manufacturing Summit, February 29- March 1, 2016.