Sight Glass Lights

There are many considerations for selecting the optimum light to illuminate your process vessel. This online guide walks you through the steps.

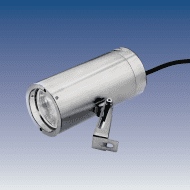

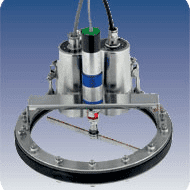

Dedicated or Separate Light Port

Often process vessels have two sight glass windows: one port for viewing and a separate port for the light. The light is typically mounted directly over the light port. To save cost or space, some vessels combine light and sight at one window. The light is typically mounted with a bracket, although sight glasses are available with integrated lights (combo style).

LED or Halogen

Traditional halogen lights use trusted incandescent light bulbs. LED lights offer brighter light, lower energy consumption, and longer life (lower maintenance costs.) Halogen light brightness is selected by wattage: 5 to 100 Watts, with 50 Watts typical. LED light brightness is selected by lumens: 1000 to 3000 lumens.

Explosion Proof or Non-Explosion Proof

Some industrial environments require explosion proof lights (ex lights) that are sealed so they cannot introduce a spark into the atmosphere. The widest selection of ex lights are halogen style, although explosion proof LED lights are also available.

Stainless Steel or Aluminum Housing

Virtually all sight glass lights use stainless steel housings. A few ex light models are available with aluminum housing, lowering their cost while removing heat more efficiently.

Available Power Supply

Most lights are available in a range of voltage options. Make sure that the model you select will work with the power you have available: 120 VAC, 24 VDC/VAC, 230 VAC, 12 VDC/VAC.